2026 Best Motorized Valve Options What to Look For?

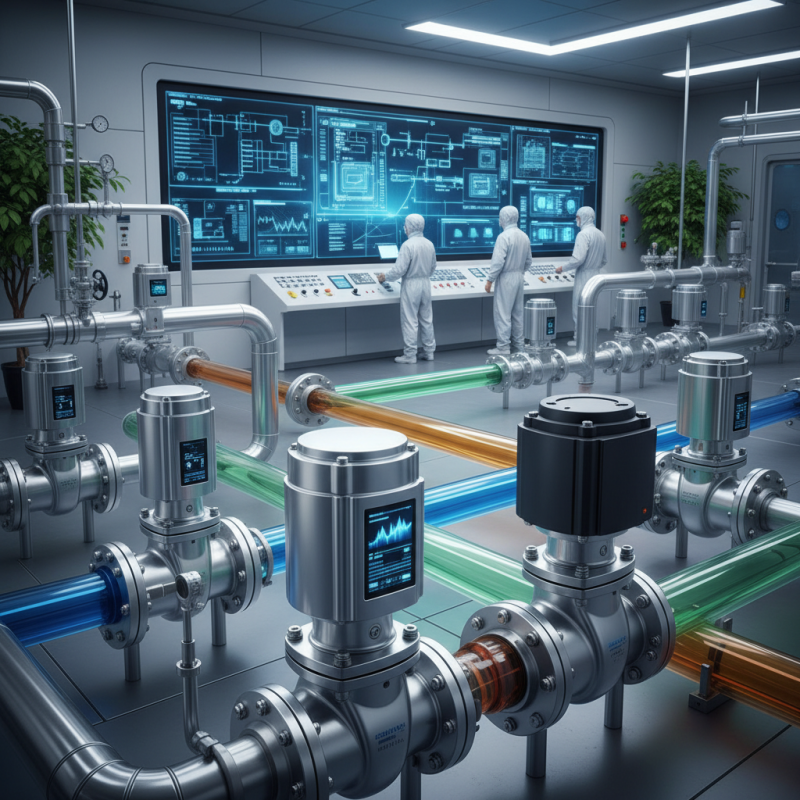

In the evolving landscape of industrial automation, the demand for efficient and reliable Motorized Valves is at an all-time high. According to a recent report by MarketsandMarkets, the global motorized valve market is projected to reach $3.87 billion by 2026, achieving a CAGR of 6.5%. This growth reflects the increasing automation trends across various sectors such as oil and gas, water treatment, and HVAC systems.

Motorized valves, integral to process control systems, offer precision and reliability. Selecting the right options can significantly enhance efficiency. Factors like actuator type, control method, and valve material play critical roles. Additionally, failing to assess these factors can lead to costly operational issues and maintenance challenges, which many industries have encountered.

Analyzing the applications and functions of motorized valves is crucial. Often, decision-makers overlook the long-term implications of their choices. Understanding specific requirements and the environment where the valves will operate can mitigate risks and improve performance. The right Motorized Valve not only improves system efficiency but also contributes to sustainability goals in industrial operations.

2026 Motorized Valve Market Overview and Key Trends

In 2026, the motorized valve market is evolving rapidly. These valves are crucial in various industries, like HVAC and automation. Choosing the right valve can be challenging due to numerous options available. Key trends indicate a growing demand for energy-efficient and smart valves. Many manufacturers focus on enhancing their designs to improve performance and reliability.

Tips: Always check for compatibility with your existing systems. Consider valves that offer real-time monitoring features. This can save time in maintenance and improve overall efficiency. Regular updates in technology are leading to more innovative designs. However, not all products live up to the hype. Some may fall short in durability or ease of use.

Investment in advanced motorized valves often pays off. Efficient valves can reduce energy costs over time. Yet, finding a product that meets your needs can be tricky. Some users report issues with installation and setup. Always read reviews and seek advice when necessary. Understand the specifications clearly for optimal performance.

Essential Features of Motorized Valves for Industrial Applications

When selecting motorized valves for industrial applications, several essential features must be considered. One key aspect is the actuator type, which directly influences efficiency. Electric actuators are commonly used, but pneumatic options are also viable. Each type has its own advantages and drawbacks, which should be assessed based on the application.

Tip: Always evaluate the power requirements of the actuator. This can significantly affect operational costs and efficiency.

Another crucial feature is the valve material. Materials such as stainless steel or PVC are popular for their durability. However, not all materials fit every application. Evaluate the chemical compatibility with the fluids being controlled. This simple step can save significant costs down the line.

Tip: Regularly inspect valve performance to detect wear and tear. Early detection leads to better maintenance strategies.

Moreover, consider the control options available. Manual overrides, remote operation, and smart integration with control systems are all worth exploring. This flexibility can enhance operational capabilities. Finding the right balance between control and automation can be challenging but essential for efficiency and productivity.

Top Manufacturers and Their Market Share in 2026

In 2026, the motorized valve market is expected to show significant growth. Several top manufacturers are shaping this landscape. These manufacturers lead in technology and innovation. Their solutions are crucial for efficient fluid control in industries.

A notable trend in the market is the increasing competition among key players. Companies strive to capture more market share through advanced features. They focus on energy efficiency, automation, and ease of installation. However, not all manufacturers meet these expectations consistently. Some may lack user-friendly designs. This could frustrate customers who prioritize seamless integration.

Another aspect to consider is customer service. Support quality varies among manufacturers. Effective technical support can significantly influence a buyer’s choice. Many customers seek reliable warranty options too. The diversity in product offerings complicates decision-making. Buyers need reliable information to navigate this crowded market.

Comparative Analysis of Valve Types: Electric vs. Pneumatic

When comparing electric and pneumatic valves, it's essential to understand their distinct characteristics. Electric valves are typically easier to manage and install. They offer precise control over flow rates, facilitating accurate system adjustments. These valves can be operated remotely, enhancing flexibility in various applications. However, they may require more maintenance due to electrical components.

On the other hand, pneumatic valves use compressed air for operation. They can be more reliable in demanding environments, as they often withstand harsher conditions. Using air as a power source can lead to faster action times. However, their setup can be more complex, and they may need additional infrastructure.

Both types have their advantages and drawbacks. Electric valves might not always perform well in extreme temperatures. Pneumatic valves could consume a lot of energy and air supply, leading to inefficiencies. Evaluating the specific needs of your application is crucial. Choosing the right valve may involve compromises, requiring careful consideration of all factors.

Future Innovations in Motorized Valve Technology and Efficiency

Future innovations in motorized valve technology are poised to significantly enhance efficiency and performance. With advances in smart control systems, these valves can now communicate seamlessly with other equipment. This integration allows for better management of fluids and process parameters. The trend of automation is not just a buzzword; it is becoming a necessity in many industries.

However, as we look towards this future, we must consider the challenges. Developing these sophisticated systems often involves higher initial costs. Not every company can afford state-of-the-art solutions. Moreover, the complexity of advanced features can lead to maintenance difficulties. Training personnel to properly handle these new technologies is crucial.

Additionally, energy efficiency is a focal point for innovation. New designs focus on reducing energy consumption while maintaining performance levels. Yet, some designs may overlook real-world applications. Balancing cutting-edge technology with practical use is vital for success. The ongoing evolution in motorized valve technology holds promise, but it also invites scrutiny. We must continuously evaluate advancements to ensure they meet actual needs.