Pet Food & Treats

The global expansion of pet humanization has many pet food manufacturers turning to CircFood for processing solutions in support of their premium pet food and dog treats. From precision dicing/slicing and dehydration of pet treats to grill marking extruded treats, we offer safe pet food processing equipment solutions for producing healthy choices on the pet food aisle.

- Home

- Industries

- Pet Food & Treats

Equipment that fits your needs

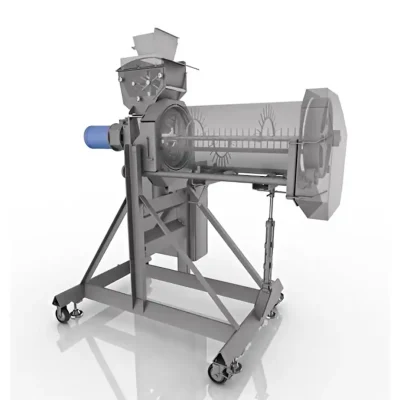

Perfecting premium dehydrated pet treats.

Increased air velocity over the surface of the product results in more uniform processing conditions during the dehydration process. Our innovative design keeps air in the “processing” zone for better performance and better product. CircFood dehydrators: the safe solution for producing healthy choices on the pet food aisle.

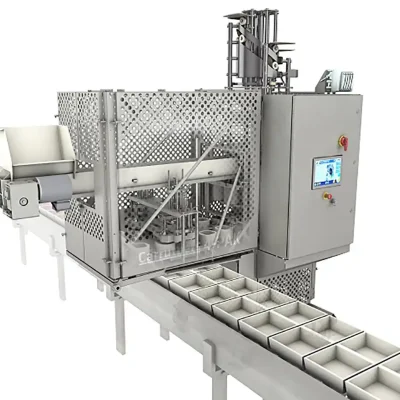

Precise uniform cuts.

Patented cutting action ensures consistent slicing for the best possible appearance and cut. Our Carruthers DuraKut™ 6000 series dicers / slicers are designed to handle the most delicate or toughest proteins while not ripping or tearing the product.