Bakery Goods & Confectionaries

Our pumping and extrusion systems allow products with particulates such as cake frosting and fillings to be transferred and portioned with gentle handing, resulting in the least amount of product damage.

- Home

- Industries

- Bakery Goods & Confectionaries

Equipment that fits your needs

CircFood’s Afoheat Select Grill Marker, equipped with gas-powered direct flame technology, is perfect for processors looking for premium grilling technology that is flexible and compact.

Our Afoheat Select Infrared Roaster is a continuous grill equipped with gas-powered infrared technology that is perfect for processors looking for premium grilling technology that is flexible and compact.

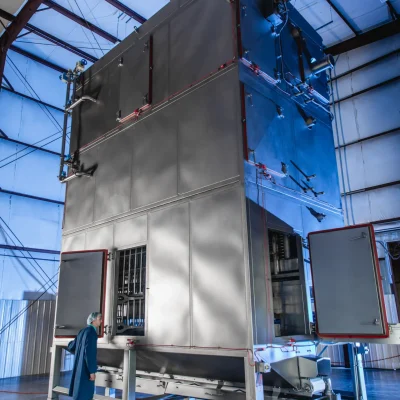

CircFood’s Large Spiral Oven, you can achieve a capacity or approximately 7,000-11,000 lbs per hour without sacrificing quality and efficiency.

Our Medium Spiral Ovens give you all the cooking power of a much bigger machine, without taking up too much room in your plant and can handle a capacity of 3,000-5,000 lbs per hour.

The CircFood Micros Spiral Oven is perfect for small processors and those just starting to move from a batch process to a continuous one.

CircFood’s Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future. It is ideal for producers expecting 750-1,800 lbs per hour capacity.

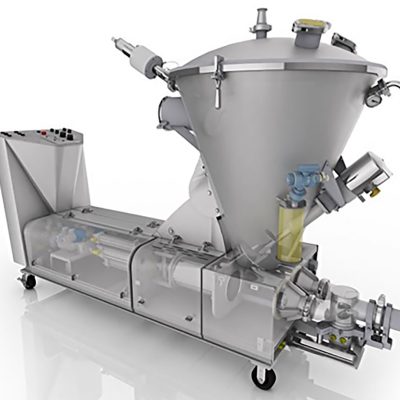

The Opti 100 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It handles up to 10,000 lbs per hour.

The Opti 120 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It handles up to 12,000 lbs per hour.

The Opti 200 Outboard vacuum stuffer and pump features a twin-piston system with a variety of hopper designs. It includes a max capacity of 20,000 lbs per hour.

With a maximum capacity of 28,000 lbs per hour, the Opti 280 features a twin-piston vacuum stuffing and pumping system that is ideal for all applications.

The Opti 340 features a twin-piston vacuum stuffing and pumping system with various hopper and accesory options. It includes a max capacity of 34,000 lbs per hour.

CircFood’s COV Volumetric Portioner is designed to volumetrically measure and portion whole muscle products with weight accuracy of +0.5%.

CircFood’s Large Spiral Oven, you can achieve a capacity or approximately 7,000-11,000 lbs per hour without sacrificing quality and efficiency.

The CircFood Medium Chiller’s horizontal airflow offers efficient freezing or chilling without the ongoing operational expense of cryogenics such as nitrogen gas.

Our Medium Spiral Ovens give you all the cooking power of a much bigger machine, without taking up too much room in your plant and can handle a capacity of 3,000-5,000 lbs per hour.

The Micro Spiral Chiller provides a reliable solution for targeting consistent product core temperatures, with optimal moisture retention.

The CircFood Micros Spiral Oven is perfect for small processors and those just starting to move from a batch process to a continuous one.

The Mini Spiral Chillers deliver ultra-hygienic design features while maximizing production capacity in a compact design.

CircFood’s Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future. It is ideal for producers expecting 750-1,800 lbs per hour capacity.

The Opti 100 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It handles up to 10,000 lbs per hour.

The Opti 120 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It handles up to 12,000 lbs per hour.

The Opti 200 Outboard vacuum stuffer and pump features a twin-piston system with a variety of hopper designs. It includes a max capacity of 20,000 lbs per hour.

With a maximum capacity of 28,000 lbs per hour, the Opti 280 features a twin-piston vacuum stuffing and pumping system that is ideal for all applications.

The Opti 340 features a twin-piston vacuum stuffing and pumping system with various hopper and accesory options. It includes a max capacity of 34,000 lbs per hour.

CircFood’s Tall Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future.

CircFood’s Vertical Crust Freezers freeze or chill the surface of every meat log to your specifications, using either Freon or ammonia.

CircFood’s XL Spiral Ovens can easly handle capacities up to 17,000 lbs per hour on a variety of products.

CircFood’s COV Volumetric Portioner is designed to volumetrically measure and portion whole muscle products with weight accuracy of +0.5%.

CircFood’s DuraKut series dicers are designed for complete cutting versatility of fresh, vacuum-tumbled, crust-frozen or cooked products into cubes or strips.

AE 5000 1D slicer is a one-dimensional slicer for continuous slicing of whole muscle, cooked or fresh log meats and other products.

Known as a meat dicer,the AE 5000 2D processes whole muscle cooked or fresh log meats and other products by slicing, dicing, and strip cutting on one unit.

The AE 5000 3D Dicer provides complete versatility for cubing of whole muscle, cooked or fresh log meats and other products.

CircFood’s Afoheat Micro Flame Grill is designed for processors moving from batch to continuous processing or with low-capacity requirements, ranging from 225-450 lbs/hr.

CircFood’s Mini Flame Grill is designed for a variety of applications including roasting, searing and grill marking of both bulk and convenience foods.

The 40-in Flame Grill includes a stand-alone HMI and can be built with either a single fan Y exhaust (12 burner) or a 2 fan straight exhaust (24 burners). Perfect for any of your surface treatment needs.

The CircFood 60-in flame grill is designed for a variety of applications with 24 burners, dual exhaust and 3 access doors

CircFood’s Afoheat Select Grill Marker, equipped with gas-powered direct flame technology, is perfect for processors looking for premium grilling technology that is flexible and compact.

Our Afoheat Select Infrared Roaster is a continuous grill equipped with gas-powered infrared technology that is perfect for processors looking for premium grilling technology that is flexible and compact.

CircFood’s Large Spiral Oven, you can achieve a capacity or approximately 7,000-11,000 lbs per hour without sacrificing quality and efficiency.

The CircFood Medium Chiller’s horizontal airflow offers efficient freezing or chilling without the ongoing operational expense of cryogenics such as nitrogen gas.

Our Medium Spiral Ovens give you all the cooking power of a much bigger machine, without taking up too much room in your plant and can handle a capacity of 3,000-5,000 lbs per hour.

The Micro Spiral Chiller provides a reliable solution for targeting consistent product core temperatures, with optimal moisture retention.

The CircFood Micros Spiral Oven is perfect for small processors and those just starting to move from a batch process to a continuous one.

The Mini Spiral Chillers deliver ultra-hygienic design features while maximizing production capacity in a compact design.

CircFood’s Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future. It is ideal for producers expecting 750-1,800 lbs per hour capacity.

CircFood’s Tall Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future.

CircFood’s XL Spiral Ovens can easly handle capacities up to 17,000 lbs per hour on a variety of products.

CircFood’s Afoheat Micro Flame Grill is designed for processors moving from batch to continuous processing or with low-capacity requirements, ranging from 225-450 lbs/hr.

CircFood’s Mini Flame Grill is designed for a variety of applications including roasting, searing and grill marking of both bulk and convenience foods.

The 40-in Flame Grill includes a stand-alone HMI and can be built with either a single fan Y exhaust (12 burner) or a 2 fan straight exhaust (24 burners). Perfect for any of your surface treatment needs.

The CircFood 60-in flame grill is designed for a variety of applications with 24 burners, dual exhaust and 3 access doors

CircFood’s Large Spiral Oven, you can achieve a capacity or approximately 7,000-11,000 lbs per hour without sacrificing quality and efficiency.

The CircFood Medium Chiller’s horizontal airflow offers efficient freezing or chilling without the ongoing operational expense of cryogenics such as nitrogen gas.

Our Medium Spiral Ovens give you all the cooking power of a much bigger machine, without taking up too much room in your plant and can handle a capacity of 3,000-5,000 lbs per hour.

The Micro Spiral Chiller provides a reliable solution for targeting consistent product core temperatures, with optimal moisture retention.

The CircFood Micros Spiral Oven is perfect for small processors and those just starting to move from a batch process to a continuous one.

The Mini Spiral Chillers deliver ultra-hygienic design features while maximizing production capacity in a compact design.

CircFood’s Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future. It is ideal for producers expecting 750-1,800 lbs per hour capacity.

CircFood’s Tall Mini Spiral Ovens are ideal for processors looking to upgrade their operations or expand their product line and maintain scalability for the future.

CircFood’s XL Spiral Ovens can easly handle capacities up to 17,000 lbs per hour on a variety of products.

The Opti 100 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It handles up to 10,000 lbs per hour.

The Opti 120 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It handles up to 12,000 lbs per hour.

The Opti 200 Outboard vacuum stuffer and pump features a twin-piston system with a variety of hopper designs. It includes a max capacity of 20,000 lbs per hour.

With a maximum capacity of 28,000 lbs per hour, the Opti 280 features a twin-piston vacuum stuffing and pumping system that is ideal for all applications.

The Opti 340 features a twin-piston vacuum stuffing and pumping system with various hopper and accesory options. It includes a max capacity of 34,000 lbs per hour.

CircFood’s COV Volumetric Portioner is designed to volumetrically measure and portion whole muscle products with weight accuracy of +0.5%.

Superior product integrity.

With its product inlet valve measuring 8 9/16” in diameter, the Opti pumping system allows products with particulates such as cake frosting to be diffused across the pump’s sheeting valve for the gentlest handling, resulting in the least amount of product damage.

High volume, continuous flow transfer.

Using our twin-piston pumping system, viscous products such as peanut butter can be extruded and deposited into various forms while maintaining product integrity.