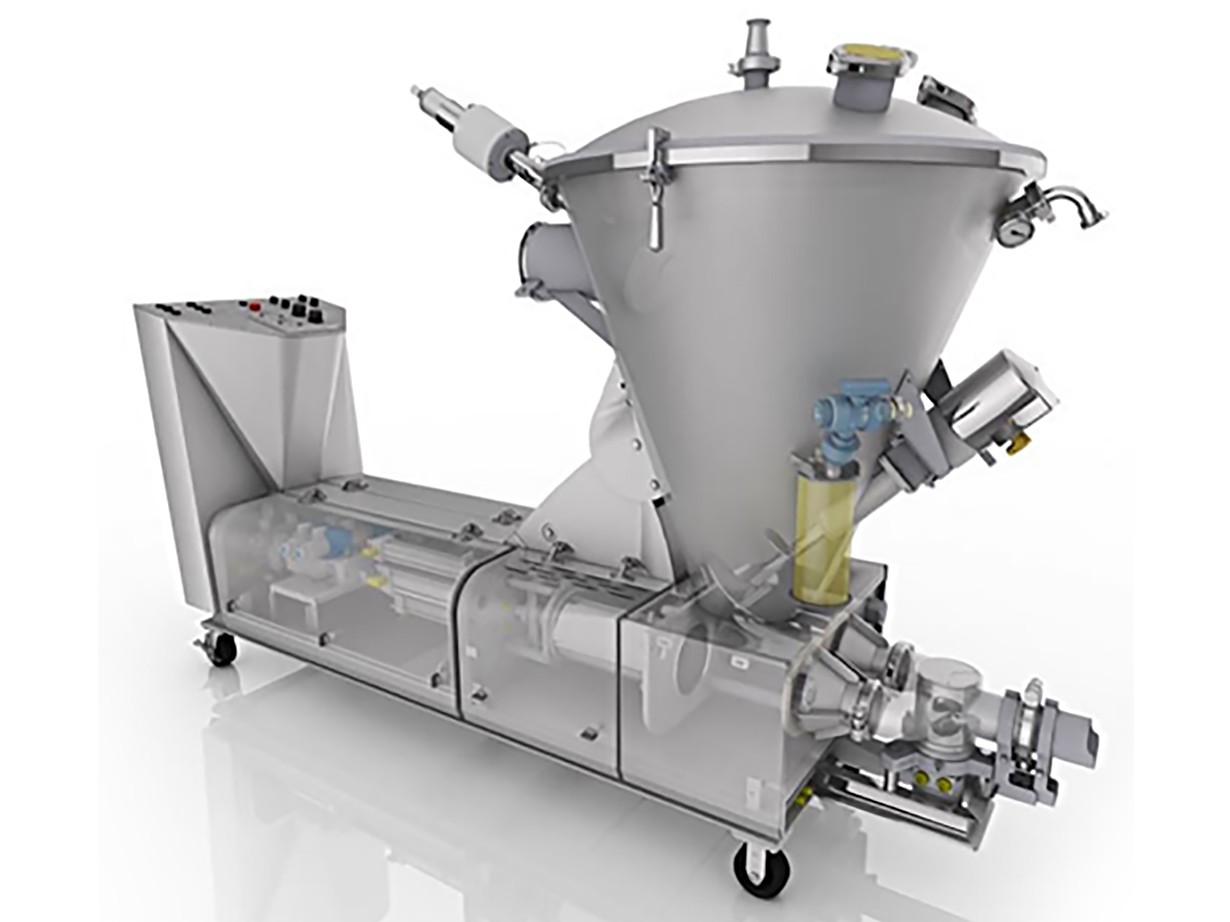

Opti 100 Vacuum Stuffer & Pump

The Opti 100 features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Maximum capacity is 10,000 lbs per hour with 250 psi pumping pressure. It is ideal for smaller application designs and can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling. CircFood’s Opti Series features the gentlest handling while providing optimal vacuumization for superior particle definition and high product integrity. The Opti 100 also includes a hydraulically driven front valve that delivers positive shifting for continuous, even product flow and more accurate portion weight control.

- Product Family: Vacuum Stuffing, Pumping & Portioning

Features

- Simplicity; no digital controls

- All the basics of a twin-piston CircFood pump at a fraction of the cost

- Small footprint and easily portable. Low-profile design accommodates space constraints and heavy-duty casters provide smooth unit mobility

- 10,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- CircFood’s unique high-differential vacuum ensures maximum removal of entrapped air resulting in denser product, more accurate portion control, and longer shelf life

- Patented, hydraulically-driven front valve delivers positive shifting for continuous, even product flow, and more accurate portion weight control

- Twin-piston pumping system designed to gently deliver products to downstream processes. The zero-slip design maintains product integrity for products ranging from the highly abrasive to whole muscle. The system is gentle on your products and reduces wear on the unit, extending its life.

- Hopper options include standard open top hopper to full vacuumed hoppers with augers for load assist for complete versatility

- Designed for easy operation & control

- Externally adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA-accepted standards

- Smaller number of parts simplifies cleanup

Specs

Piston Diameter: 7 1/8″ (181 mm)

Piston Stroke: 14″ (355 mm)

Maximum Capacity: 10,000 lbs/hr (4536 kg/hr)

Maximum Volume (based on water): 20 gpm (76 lpm)

Product Outlet: 4″ (102 mm)

Max. Product Pressure: 250 psi (17 bar)

Machine Weight: 2,300 lbs (1043 kg)

Electrical: 110V, 10Amp, 1-Ph

Air Requirements: 3 CFM at 100 psi

Power Unit: 25 HP, 230/460V, 3-Ph/60HZ, 68/34 AMP

Power Unit Max Ver: 40 HP, 234/460V, 3-Ph/60HZ, 52/104 AMP

Cooling Water: Up to 8 gpm

Vacuum Pump: 7.5 HP, 130 CFM, 230/460V, 22/11 AMP