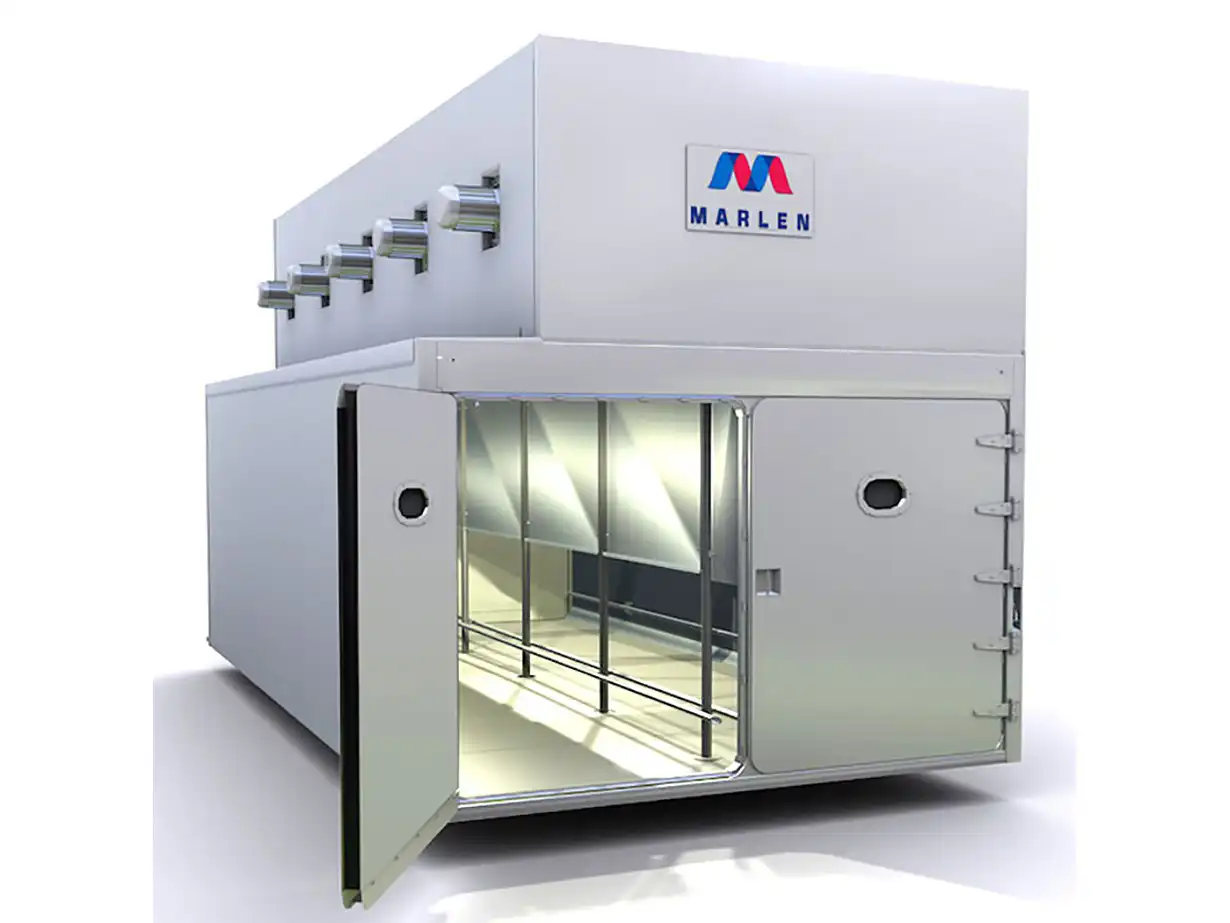

Blast Chill Cell

The CircFood Blast Chill Cells feature a continuous chill process, allowing maximum heat reduction at a uniform rate, resulting in faster chill times, higher yields, and greater product uniformity while achieving maximum energy savings. Custom chilling recipes allow the product to aspirate naturally, giving up a precise amount of moisture and no more. This recipe not only brings about rapid stabilization but does so with optimum uniformity — no “hot spots”, no errant crusting. The chillers also have optimized evaporator coil which allow for faster chilling at higher refrigerant temperatures allowing you to save money in refrigeration cost.

- Product Family: Batch Ovens,Chillers and Industrial Dehydrators,Smokehouses

Featured Video

Blast Chill Cell

Features

- Variable speed fans allow you to chill product faster using brine chill cabinets with more uniformity and in a sanitary environment

- CircFood’s variable speed fans run at low speed during “wet coil” conditions. Then, as desired moisture removal is nearly complete, fan speed increases and the system shifts to a lower temperature “dry coil” condition. This design significantly reduces shrinkage and prevents errant crusting

- The CircFood chill cell control system stores and controls chilling “recipes,” logs processes and product temperature data for HACCP verification. This makes the system efficient by producing repeatable and uniform results allowing for higher yields.

- Exacting control for consistent high-yielding quality throughout the load, batch after batch

- Every design element is aimed at producing product that is uniform in terms of temperature, color and yield

- Optimized evaporator coil allows for faster chilling at higher refrigerant temperatures allowing you to save money in refrigeration cost

- CircFood continuous chill process is designed and constructed to maximize uptime through easy operation and maintenance

- Insulated, all welded stainless steel construction with built-in CIP system

- Insulated Drain Pan Under Coil

- CircFood’s Safety-First emphasis is designed and built into every product

- Service-friendly design with logical and easy access to essential areas

- Made in the USA

Specs

Custom Designed around your product, process and facility

Robust construction, easy to maintain

Patented monolithic floor design minimizes harborage areas

Powis 6000 controls – designed specifically for HACCP documentation to answer the “who, what, when, where and why” for your process

SmartChill control allows you to chill faster with reduced refrigeration requirements

Meets the USDA Appendix B and Canadian Food Inspection Agency chilling guidelines on most product

Provides uniform airflow conditions and precise temperature control for fast chill times and superior process uniformity

World-class training