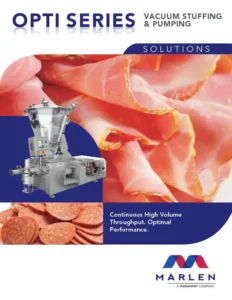

Opti 200 Outboard Vacuum Stuffer & Pump

The Opti 200 Outboard features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. It includes a maximum capacity of 20,000 lbs per hour with 250 psi pumping pressure. The Opti 200 Outboard is ideal for applications requiring higher speed output. It can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

- Product Family: Vacuum Stuffing, Pumping & Portioning

Features

- Totally self-contained vacuumize filler 25 horsepower hydraulic unit, 5 horsepower 71 cfm vacuum pump, air-cooled, including motor starters

- 20,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- CircFood’s proven twin-piston pumping system design; largest product opening on the market

- Twin position and sleeve design allows for the industry’s highest vacuum pumping available eliminating the need for inferior dual-stage vacuumization process

- Designed with two modes of pumping for better pressure control or controlled flow rate which allows the plant to tailor the equipment to the application

- Opti Vacuum Fillers and Suffing Pumps can achieve the highest vacuumization in the industry for excellent color retention results

- Twin-Piston Pumping Chamber features an 10° incline that increases product flow into the pumping chamber. Easier loading into the pumping chamber ensures maximum operating efficiencies.

- CircFood’s patented design eliminates metal-to-metal contact within the pump chamber which eliminates regular costly part replacement and downtime

- State-of-the-art control panel with built-in self-diagnostic feature helps reduce downtime

- Unobstructed patented 4-in hydraulically driven front valve for positive shifting and even product flow

- Opti Vacuum Fillers and Suffing Pumps design reduces loose parts and simplifies cleaning

- Hopper options include standard open top hopper to full vacuumed hoppers with augers for load assist for complete versatility

- High differential vacuum stuffers on vacuumized units ensure maximum removal of entrapped air for better weight control, shelf life, and casing savings

- Patented externally adjustable diffuser valve with 8-in inlet enables the OPTI-Series to maximize the product’s exposure to vacuum

- Power-Tilt Hopper is hydraulically operated from the touchpad control panel for full access into all product areas during cleanup

- Designed for easy operation and control with diagnostic capabilities

- State-of-the-art control panel

- Large recipe storage capacity. Easy screen navigation. 8.4-in touch screen.

- Foreign language customizing

- Externally adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA-accepted standards

- Smaller number of parts simplifies cleanup

- Made in the USA

Specs

Piston Diameter: 8-9/16″ (217 mm)

Piston Stroke: 10″ (250 mm)

Maximum Capacity: 20,000 lbs/hr (9071 kg/hr)

Maximum Volume (based on water): 37.8 gpm (143 lpm) based on water

Product Outlet: 4″ (102 mm)

Max. Product Pressure: 250 psi (17 bar)

Machine Weight: 3,400 lbs (1542 kg)

Pump Electrical: 110V, 10AMP, 1-Ph

Pump PLC: 24 Volt DC

Air Requirements: 3 CFM at 100 PSI

Power Unit: 40 HP, 230/460V, 3-Ph/60HZ, 104/52 AMP

Cooling Water: Up to 8 GPM

Vacuum Pump: 7.5 HP, 130 CFM, 230/460V, 22/11 AMP

Industry Applications

Videos

OPTI 200 Pump Video