1-PAK Elephants

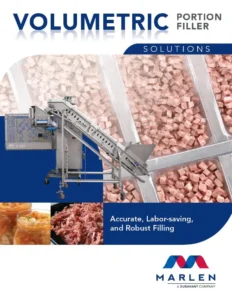

CircFood’s Carruthers Single-Station Rotary Volumetric Filler is designed for filling food products into a wide range of container types – up to 5 lbs per portion. Our Carruthers 1-PAK filler is ideal for R&D purposes or for low-production applications such as hot or cold shredded meats or freshly diced food products.

- Product Family: Filling

Features

- Designed as a single-station rotary volumetric filler for portioning of dry products such as raw or cooked meats, and vegetables

- Designed to deposit portions from a few ounces to over five pounds with amazing accuracy and product appearance

- Our patented technology helps processors save labor costs and improve fill weight accuracy and processing speeds for these hard-to-fill products

- Portion shape, size and placement are all defined and placed accurately to keep seals and containers clean

- Our target fill sonic sensors assure maximum yields by achieving fill weight accuracy within each fill station

- Our unique patented slide-fill process surrounds over-sized and random shaped product while portioning to reduce damage

- Designed to eliminate the need for moisture. Products flow gently without adding liquid which allows seasonings to stay on, assuring better quality in taste and appearance.

- Our design allows the product to be positively fed through the machine, this means no bridging as it does not rely on vacuum or gravity

- Designed and constructed to maximize uptime through easy operation and maintenance

- Extensive design effort assures that our 1-PAK Filler is easy to clean

- Adjust fill weights “On the Fly.” Adjustments can be made at start-up or in production. No wasted time or product “dialing in”

- Fully mechanical design using a single motor which makes troubleshooting easier

- Made in the USA

Carruthers 1-PAK rotary volumetric filler is available in many portioning configurations to suit your container line, whether continuous or indexing, single or multi-lane, trays, pouches, thermoform packages, jars, cups, cans.

Rigid Containers (Cans/Jars)

- Containers fed through filler

- Bottom fill capability for smallmouth containers

- Double pass capability for large or tall portions

- Ability to compact portions in container for headspace

Single-Lane Target Depositing

- Designed for continuous moving ‘entree’ and ‘ready meal’ assembly lines at low to high speeds

- Filler synchronized to moving containers

- Containers such as trays, bowls, tortillas

- Portioning pockets synchronize and move with container during discharge to ensure smooth transfer and accurate placement

- Adjustable product placement in both directions

Multi-Lane Target Depositing

- Designed for indexing Thermoform/rollstock or multi-lane tray/cup sealing machines

- Indexing mode for filler

- Simple electronic handshake signal with packaging machine

- Cantilevered design; no hardware needs to be attached to packaging machine

Vertical Pouches

- Pre-made pouches or bags

- Filler directly interfaced to pouch handling system for smooth transfer

- Simplex or duplex mode

Specs

Fill Stations: 1

Slide or Bowl Fill: Slide

Maximum Portion Diameter: 5.875″ (149.23 mm)

Maximum Portion Height: 8″ (203.2 mm)

Maximum Portion Weight: 5 lbs (2.28 kg)

Industry Applications

Documents/Resources

Videos