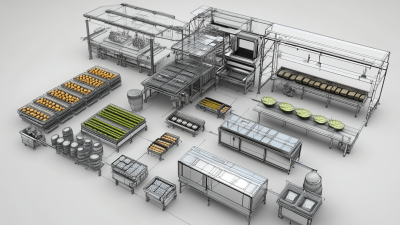

7 Best Practices for Optimizing Pet Food Processing Equipment Efficiency

In the competitive landscape of the pet food industry, maximizing efficiency in manufacturing processes is paramount for success. As companies strive to meet the growing demand for high-quality pet food, optimizing the performance of Pet Food Processing Equipment becomes a critical focus. The right approach not only enhances productivity but also improves product quality and reduces operational costs. This blog explores seven best practices that can help pet food manufacturers streamline their operations, ultimately fostering a more sustainable and profitable business model. By implementing these strategies, companies can ensure their pet food processing equipment operates at peak performance, aligning with industry standards while catering to the evolving needs of pet owners.

Understanding the Importance of Equipment Efficiency in Pet Food Processing

In the competitive world of pet food manufacturing, understanding the importance of equipment efficiency is paramount for success. Efficient processing equipment directly impacts production timelines, product quality, and overall operational costs. By optimizing the processing machinery, manufacturers can minimize energy consumption, reduce waste, and enhance the consistency of their products. This can lead to improved customer satisfaction and brand loyalty, as pets receive high-quality nutrition in their meals.

Moreover, investing in cutting-edge technology and regular maintenance not only prolongs the lifespan of the equipment but also ensures it operates at peak performance. Implementing best practices such as routine inspections, staff training, and performance monitoring can identify inefficiencies early on and facilitate timely adjustments. This proactive approach helps in maintaining optimal processing conditions, resulting in a smoother workflow and increased output. Ultimately, prioritizing equipment efficiency is not just about economic benefits; it reflects a commitment to producing safe, nutritious, and high-quality pet food that meets the evolving demands of pet owners.

Key Performance Indicators for Measuring Equipment Efficiency

When it comes to optimizing pet food processing equipment efficiency, understanding and measuring Key Performance Indicators (KPIs) is crucial. KPIs, such as Overall Equipment Effectiveness (OEE), play a vital role in determining how well machinery performs in terms of availability, performance, and quality. According to a report by the International Society of Automation, machinery operating at optimal OEE can boost productivity by up to 20%, directly impacting overall production costs and profitability.

Another important KPI in pet food processing is the Rate of Product Changeover, which indicates the efficiency of equipment in transitioning between different product lines. The Pet Food Institute states that an efficient changeover can reduce downtime by an average of 30-50%. By closely monitoring this metric, manufacturers can significantly enhance their operational efficiency and responsiveness to market demands. Additionally, tracking energy consumption during processing can help identify areas for improvement in sustainability efforts. Reports show that energy-efficient equipment can reduce operational costs by nearly 10-15%, aligning profitability with environmentally responsible practices.

Comparative Analysis of Traditional vs. Modern Processing Technologies

The evolution of pet food processing technologies has significantly impacted the efficiency of production lines. Traditional processing methods often rely on batch systems that can lead to inconsistencies in product quality and longer processing times. For example, conventional extrusion processes may struggle with heat management, resulting in uneven cooking and nutrient retention. These limitations can hinder a manufacturer’s ability to meet market demands and maintain competitive pricing.

The evolution of pet food processing technologies has significantly impacted the efficiency of production lines. Traditional processing methods often rely on batch systems that can lead to inconsistencies in product quality and longer processing times. For example, conventional extrusion processes may struggle with heat management, resulting in uneven cooking and nutrient retention. These limitations can hinder a manufacturer’s ability to meet market demands and maintain competitive pricing.

In contrast, modern processing technologies, such as continuous flow systems and advanced extrusion techniques, allow for better control over production parameters. These innovations not only enhance the quality and nutritional value of pet foods but also streamline production workflows. Continuous systems reduce downtime between batches, thereby increasing overall output and efficiency. Furthermore, the integration of automation in modern facilities enables real-time monitoring and adjustments, leading to improved safety standards and compliance with regulatory requirements. The shift from traditional to modern processing methods represents a pivotal moment in the pet food industry, fostering both sustainability and profitability in a highly competitive market.

Innovative Techniques for Reducing Downtime and Enhancing Output

In the rapidly evolving pet food industry, optimizing processing equipment is crucial for reducing downtime and enhancing output. Recent studies indicate that equipment failures account for up to 40% of production downtime, negatively impacting profitability and operational efficiency. Implementing predictive maintenance techniques, powered by IoT technology, can help identify potential issues before they cause significant disruptions. Reports show that companies utilizing predictive maintenance can reduce unplanned downtime by up to 50%, demonstrating the importance of proactive management for improving operational performance.

Moreover, the integration of automation and real-time monitoring systems is transforming the landscape of pet food processing. According to the Global Pet Food Market Report, the automation of processing lines can increase production rates by at least 20%, leading to substantial output enhancements. These innovative techniques not only streamline operations but also ensure consistent product quality, which is paramount in gaining consumer trust. By embracing these advancements and focusing on minimizing equipment inefficiencies, manufacturers can create a more robust and responsive production environment, ultimately positioning themselves for success in a competitive market.

Case Studies: Successful Efficiency Optimizations in Pet Food Facilities

Maximizing efficiency in pet food processing facilities has become a critical focus for manufacturers looking to enhance productivity and reduce operational costs. According to a report by the American Pet Products Association, the pet food market is projected to reach $113 billion by 2025. As this market expands, optimizing processing equipment is essential for staying competitive. One notable case study involved a leading pet food manufacturer that implemented a predictive maintenance program, resulting in a 25% reduction in equipment downtime. By utilizing real-time data analytics, they were able to foresee potential malfunctions and address them proactively, showcasing how technology can lead to significant efficiency gains.

Another successful efficiency optimization occurred in a facility that adopted automated blending technology. This system not only streamlined the formulation process but also improved ingredient consistency and reduced waste by 15%. Research from the Food Processing Suppliers Association suggests that automation can increase production rates by up to 50%, making it a critical investment for pet food manufacturers seeking to meet growing consumer demand. These case studies illustrate the tangible benefits of embracing innovative technologies to enhance equipment efficiency, allowing manufacturers to improve both their bottom line and product quality in a competitive market.

7 Best Practices for Optimizing Pet Food Processing Equipment Efficiency - Case Studies: Successful Efficiency Optimizations in Pet Food Facilities

| Practice | Description | Before Optimization | After Optimization | Percentage Improvement |

|---|---|---|---|---|

| Equipment Maintenance | Implementing a routine maintenance schedule to reduce downtime. | 85% uptime | 95% uptime | 11.76% |

| Energy Audits | Conducting audits to identify energy waste in processes. | 300,000 kWh/year | 250,000 kWh/year | 16.67% |

| Process Automation | Implementing automated systems to reduce manual labor. | 70% manual | 30% manual | 57.14% |

| Staff Training | Training staff on efficient equipment operation. | 80% efficiency | 95% efficiency | 18.75% |

| Ingredient Quality Control | Monitoring ingredient quality to ensure optimal processing. | 3% defect rate | 1% defect rate | 66.67% |

| Lean Manufacturing | Applying lean principles to reduce waste in production. | 40% wasted material | 20% wasted material | 50% |

| Data Analysis | Utilizing data analytics for accurate forecasts and decision-making. | Low prediction accuracy | High prediction accuracy | Significant improvement |

Related Posts

-

The Ultimate Showdown of Commercial Meat Processing Equipment Features and Benefits

-

How to Choose the Best Meat Butcher Equipment for Your Business Needs

-

Leading Global Manufacturers in Industrial Food Processing Equipment Exporting Excellence

-

Comprehensive Blueprint for Selecting Food Processing Equipment

-

How to Identify Top Suppliers for Best Food Processing Industry Equipment Globally

-

7 Top Reasons Turkey Processing Equipment is Essential for Global Suppliers