How to Choose the Best Meat Processing Equipment for Your Needs?

Choosing the right Meat Processing Equipment can be daunting. With various options available, how do you know what suits your business? As industry expert John Smith stated, "Investing in the right equipment is crucial for quality and efficiency."

Your equipment choices impact productivity and product quality. For example, think about your specific needs. Do you require sausage stuffers or grinders? Each type of Meat Processing Equipment serves a different purpose.

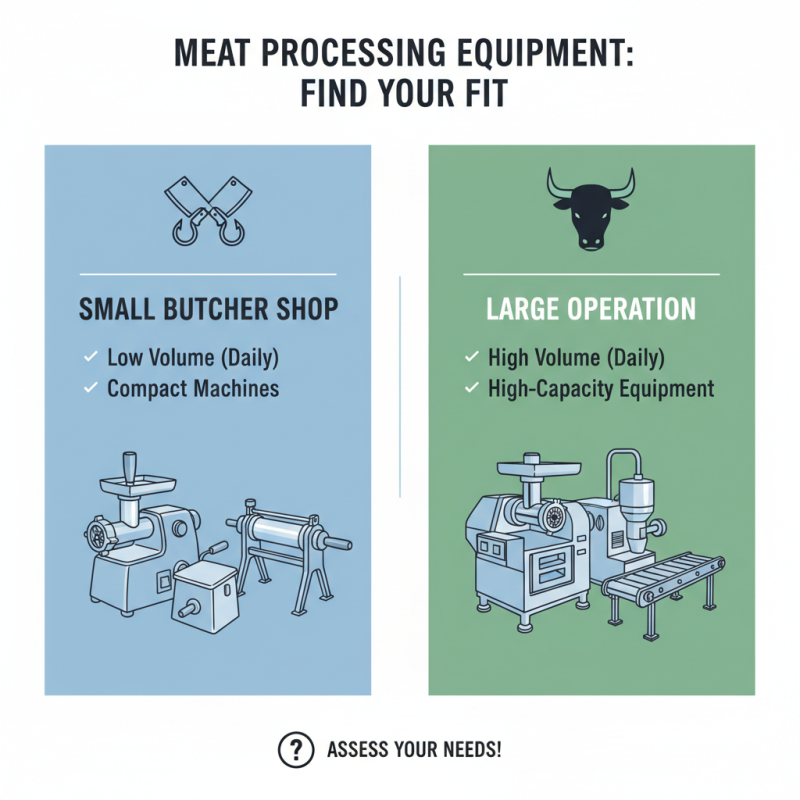

Moreover, consider the size of your operation. Smaller businesses may not need industrial-grade machines. Yet, larger operations may struggle with inadequate equipment. It's essential to balance your budget with quality. Reflect on past purchases and their outcomes. What worked well, and what didn't? Finding the best equipment is not just about brands. It’s about meeting your individual needs effectively.

Understanding Different Types of Meat Processing Equipment Available Today

When selecting meat processing equipment, it's crucial to understand the various types available. Each type serves distinct purposes and meets different needs. There are grinders, slicers, and mixers, each essential for specific tasks. Grinders are perfect for making ground meat. They come in various sizes and capacities. Slicers provide uniform cuts for deli meats or steaks. A good slicer saves time and ensures consistency.

Another vital piece of equipment is the mixer. It combines ingredients for sausages or meat patties. Mixing evenly is crucial to enhance flavor and texture. Keep in mind, choosing the right equipment can be overwhelming. You might not know the exact specifications needed for your operations. It’s good to list your requirements before diving into purchases. Avoid overspending on machines you may not fully utilize.

Don’t forget about maintenance and durability. Equipment needs regular care to function optimally. Some machines may seem reliable but require constant repairs. Consider your production volume. It helps in making smarter decisions about what to buy. Finding the balance between quality and cost can be challenging. Every choice requires careful thought.

Meat Processing Equipment Types and Their Usage

Assessing Your Meat Processing Needs: Volume, Type, and Product Specifications

Choosing the right meat processing equipment starts with understanding your unique needs. Assess the volume of meat you process daily. Are you a small butcher shop or a larger operation? Smaller businesses may need compact machines. Larger operations, on the other hand, require high-capacity equipment to keep up with demand.

Next, consider the type of meat you handle. Pork, beef, and poultry have different processing requirements. Different types of machines cater to specific meats, like grinders or slicers designed for tougher cuts. You’ll want to be precise here; the wrong type can slow you down. Additionally, check product specifications closely. Features like adjustable speeds and various attachments can enhance efficiency.

Lastly, think about the space available for equipment. Limited space might mean you compromise on features or capacity. This can be a tricky area; balancing size and functionality requires careful thought. Reflect on the growth of your business as well. Will your current setup meet future needs? Evaluate your operation routinely. Adjustments may be necessary as demands change.

Evaluating Equipment Performance: Key Metrics and Industry Standards

When selecting meat processing equipment, evaluating performance metrics is crucial. Key industry standards include capacity, efficiency, and durability. For example, the average meat processing plant achieves a yield of about 75%. This means that 75% of raw material is transformed into marketable products. Efficient equipment can increase this yield significantly.

Speed is another important metric. An effective meat grinder should process at least 1000 pounds per hour for larger operations. However, not all machines sustain this speed effectively. Some may experience overheating after short periods. This can lead to production delays and increased maintenance costs.

Durability also plays a vital role. Research shows that equipment with stainless steel components lasts 20% longer than those made from other materials. Regular inspections and preventive maintenance can extend the lifespan of machines. However, not all operators prioritize this, leading to unexpected breakdowns and replacement costs. Assessing these metrics helps ensure that you choose the best equipment for your specific needs.

Key Features to Look for in Meat Processing Equipment: Safety and Efficiency

When selecting meat processing equipment, focus on safety and efficiency. Safety is paramount. According to industry reports, equipment-related injuries account for about 25% of workplace incidents in processing facilities. Look for features like automatic shut-off systems. These can help prevent accidents. Additionally, stainless steel designs are crucial. They resist bacteria growth, ensuring hygiene.

Efficiency also plays a vital role. Data shows that upgrading to newer equipment can improve productivity by up to 30%. Features like energy-efficient motors can cut energy costs significantly. A good meat slicer should process up to 50 pounds of meat per hour. Quality grinders should reduce waste effectively, turning scraps into value-added products.

Don't overlook maintenance aspects. Some equipment may require more frequent servicing. This can lead to unexpected downtime. Reflect on how the downtime will affect your operations. Prioritize features that can minimize these issues. Evaluate your specific needs carefully. Not every piece of equipment will fit every operation ideally.

How to Choose the Best Meat Processing Equipment for Your Needs?

| Feature | Importance | Specifications to Consider |

|---|---|---|

| Safety Features | High | Emergency stops, safety guards, and food-grade materials |

| Efficiency | High | Processing speed, energy consumption, and maintenance requirements |

| Versatility | Medium | Ability to handle different types of meat and processing methods |

| User-Friendliness | High | Ease of use, clear controls, and operator training |

| Durability | High | Material quality, warranty, and expected lifespan |

| Compliance | High | Meeting local health regulations and industry standards |

Investing in Quality: Cost Analysis and Long-Term Savings in Meat Processing

When investing in meat processing equipment, a comprehensive cost analysis is essential. According to industry reports, the initial cost of high-quality equipment can be significant, but the long-term savings often outweigh the costs. For example, durable machines reduce maintenance and downtime, saving up to 20% operational expenses annually.

Consider this: equipment failure often leads to costly delays. A reliable grinder, for instance, can make a difference. It ensures consistent product quality and minimizes waste. These factors contribute to a stronger bottom line over time.

Tips: Assess your production volume. Select equipment that matches your scale. Think about energy efficiency, too. A machine that uses less energy can cut costs. Research shows that upgrading to energy-efficient models can save facilities an average of 15% on utility bills.

Investing wisely in quality equipment can provide significant returns. However, buyers must avoid hasty decisions. Analyze their specific needs carefully. Understand that not every shiny model is the best choice. Balance cost with efficiency to optimize your operations.

Related Posts

-

Maximize Your Meat Butcher Equipment Sales at the Record Breaking 137th Canton Fair 2025

-

7 Secrets to Choosing the Best Meat Equipment for Your Business

-

5 Essential Trends in Commercial Meat Processing Equipment for Global Buyers

-

The Evolution of Meat Processing Equipment for Global Buyers

-

Leading Industrial Meat Processing Equipment Manufacturers from China at the 137th Canton Fair

-

Excellence in Manufacturing Transforming Global Meat Processing with Chinese Innovation