Comprehensive Blueprint for Selecting Food Processing Equipment

In the rapidly evolving landscape of the food industry, the selection of appropriate Equipment Food Processing has become a critical differentiator for success. As businesses strive to meet increasing consumer demands and regulatory standards, the right equipment can lead to enhanced efficiency, improved product quality, and streamlined operations. This blog aims to provide a comprehensive blueprint to assist food manufacturers, small business owners, and culinary entrepreneurs in making informed decisions when it comes to choosing the most suitable processing equipment.

From understanding the various types of equipment to evaluating suppliers and technology, this guide delves into the essential factors that influence equipment selection. With insights into cost-effectiveness, sustainability, and scalability, readers will be equipped with the necessary knowledge to navigate the complexities of the food processing industry. Whether you are a seasoned professional or just starting, our goal is to empower you to make choices that will not only enhance productivity but also align with your long-term business objectives.

Key Factors to Consider When Choosing Food Processing Equipment

When selecting food processing equipment, it is essential to consider various product types and their specific needs. The global industrial food processing market was valued at an impressive $64.1 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of over 4.5% from 2024 to 2032. This growth highlights the increasing demand for tailored equipment that can handle specific food products, such as beef, pork, chicken, and their derived forms like sausages and ground meat. For instance, meat slicing and grinding equipment are pivotal in processing meat. With a market size of $3.5 billion in 2022, expected to reach $5.1 billion by 2030, these machines are essential for ensuring high efficiency and quality in meat preparation. Factors such as the equipment's efficiency in handling bulk processing, sanitation standards, and ease of maintenance must be evaluated to meet the stringent industry demands. Moreover, the rise of plant-based alternatives is reshaping the food processing landscape. The market for plant-based bars is experiencing significant growth, driven by consumer preferences for healthier, sustainable options. This trend underscores the necessity for adaptable processing equipment capable of managing diverse formulations, from protein bars to granola snacks, ensuring that food manufacturers stay competitive in this evolving marketplace. The selection of food processing equipment should be guided by these key factors—efficiency tailored to specific food products, compliance with safety standards, and adaptability to changing market trends. This comprehensive approach will drive success in the increasingly competitive food industry landscape.

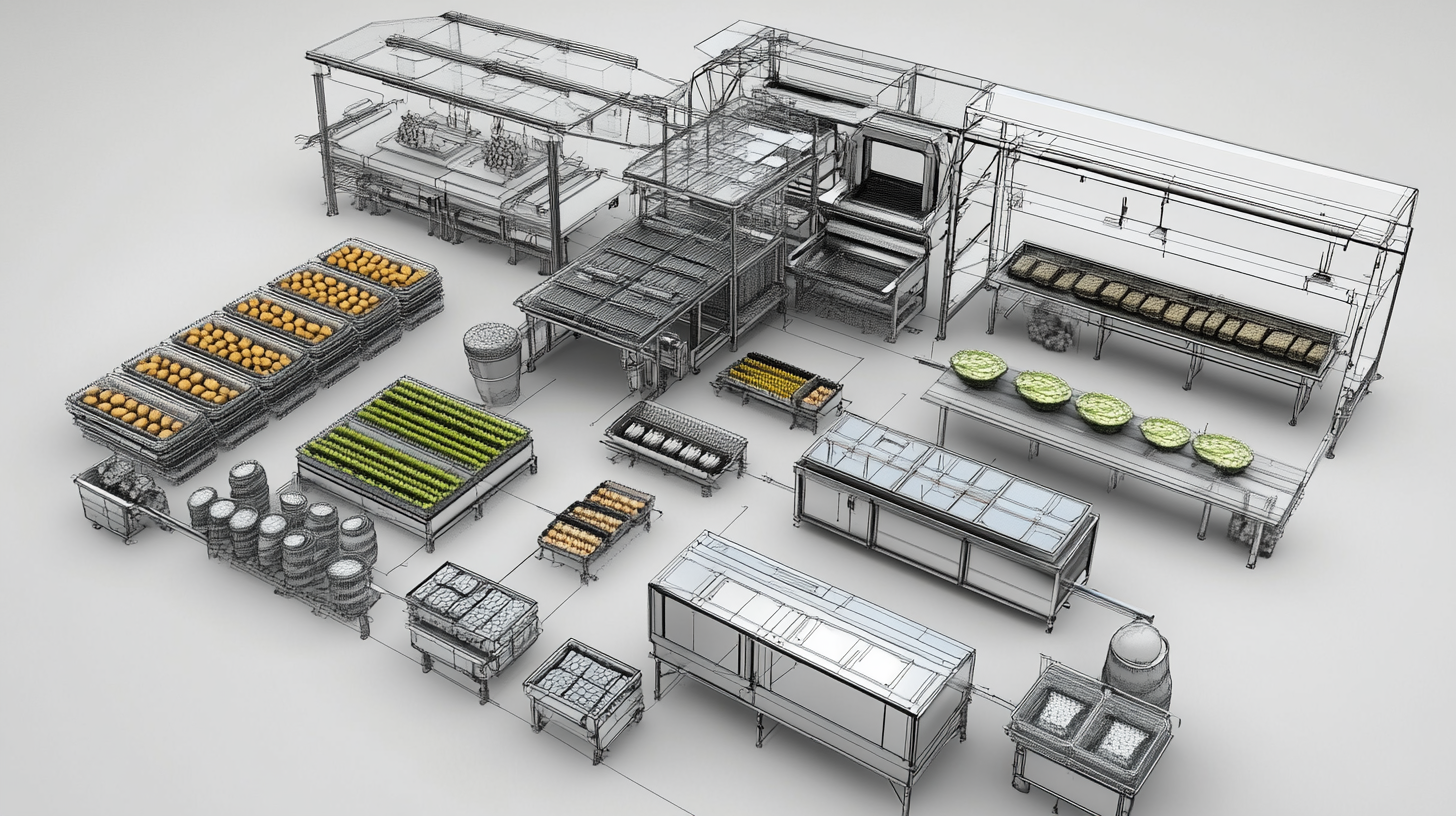

Understanding Different Types of Food Processing Machinery

When it comes to choosing food processing machinery, understanding the different types available is crucial for any business in the food industry. Various machines serve unique purposes, and recognizing these differences can greatly enhance efficiency and productivity. For example, mixers are essential for blending ingredients uniformly, while grinders are designed for breaking down larger food items into smaller, manageable pieces. Each piece of equipment plays a specific role in the overall processing workflow, influencing not only the quality of the final product but also the speed of production.

Additionally, food processors can be categorized based on their functions, such as cutting, cooking, or drying. Cutting machines, like slicers and dicers, are vital for preparing vegetables and meats, ensuring uniformity that is important for cooking and presentation. On the other hand, cooking equipment, such as steamers and fryers, introduces heat to transform raw ingredients into delicious meals. Lastly, drying machines are key for extending the shelf life of various food products by removing moisture, making them essential for snacks and preservation. Understanding these categories allows businesses to invest in the right equipment tailored to their specific needs, ultimately leading to improved operational flow.

Investing in the correct type of machinery not only impacts production efficiency but also inventory management and labor costs. Automated systems in food processing equipment can reduce manual labor while enhancing precision and maintaining hygiene standards. Furthermore, considering the capability of machinery to handle specific dietary or production trends, such as gluten-free or organic options, can lead to better market positioning. By deeply understanding the various types of food processing machinery and their functions, businesses can make informed decisions that support their growth and adapt to evolving consumer demands.

Evaluating Cost vs. Efficiency in Equipment Selection

When it comes to selecting food processing equipment, the balance between cost and efficiency is crucial for any business looking to thrive in a competitive market. Investing in high-quality machinery can significantly improve production capabilities, but the initial financial outlay can be daunting. It's essential to evaluate not just the purchase price but also the long-term operating costs. This includes factors such as energy consumption, maintenance requirements, and the expected lifespan of the equipment.

Efficiency should be at the forefront of any decision-making process. More efficient machines can often lead to significant time and cost savings in the long run, even if their initial price tag is higher. For example, a piece of equipment that uses less energy and requires fewer repairs can quickly pay for itself through reduced operational costs. Furthermore, efficient equipment reduces waste and supports sustainability goals, which is increasingly important in today’s environmentally conscious market.

Ultimately, businesses must conduct a thorough cost-benefit analysis to identify equipment that not only fits their budget but also enhances their production capabilities. Investing time in researching and comparing different models will pay dividends, helping food processors make informed decisions that contribute to their bottom line while maintaining product quality and operational efficiency.

The Importance of Compliance with Food Safety Standards

In the food processing industry, compliance with food safety standards is not merely a regulatory requirement; it is a fundamental building block for the success and sustainability of any operation. Selecting the right food processing equipment entails more than assessing efficiency and costs; it also requires a thorough understanding of the safety standards that govern the industry. Equipment must be designed and constructed to prevent contamination, facilitate cleaning, and ensure proper functioning in line with health regulations.

Food safety standards, such as those established by the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), outline critical specifications that processing equipment must meet. This includes materials used in construction, which should be non-reactive and easy to sanitize. Furthermore, equipment should be equipped with features that minimize risks, such as enclosed systems that prevent exposure to contaminants. By prioritizing compliance in the selection process, businesses not only adhere to legal mandates but also build trust with consumers, enhance their brand reputation, and mitigate the risk of recalls and liabilities.

Moreover, investing in compliant equipment contributes to operational efficiency by reducing downtime associated with safety inspections and potential penalties. Regularly updated standards reflect the latest research and technology in food safety, making it imperative for processing companies to stay informed and choose equipment that aligns with these evolving requirements. By doing so, companies can ensure that they are not only meeting current standards but are also prepared for future advancements in food safety practices.

Maintenance and Support: Ensuring Longevity of Your Equipment

Maintenance and support are vital components in ensuring the longevity and performance of food processing equipment. Just as highlighted by Matt Burke and Joni Zein of Johnson Controls on the importance of service in building performance, the same principles apply when considering the intricate machinery utilized in processing food. Regular maintenance not only enhances operational efficiency but also reduces the risk of unexpected breakdowns—an essential factor in the food industry where safety and compliance are paramount.

According to the latest insights from the Medical Equipment Maintenance Market report, the increasing focus on preventive maintenance strategies has seen significant growth, driven by the need to ensure equipment reliability and compliance with stringent health and safety regulations. This trend is echoed in other sectors, including food processing, where companies are investing in comprehensive maintenance plans that extend equipment life while improving product quality and operational efficiency.

Moreover, recent acquisitions, such as Southeastern Laundry Equipment Sales’ purchase of Cochrane Repair Service, showcase a growing recognition within the industry of the necessity for enhanced service and support capabilities. This move indicates a proactive approach to servicing and maintaining equipment, ensuring that support is readily available at every stage of the equipment lifecycle. Investing in targeted support, much like John Deere's comprehensive Lifecycle Service Solution, can significantly influence the durability and performance of food processing equipment, making it a strategic imperative for businesses aiming for long-term success.