Leading Global Manufacturers in Industrial Food Processing Equipment Exporting Excellence

In the ever-evolving landscape of the food industry, the role of Industrial Food Processing Equipment has never been more critical. As global demand for efficiency and quality rises, manufacturers are pioneering innovative technologies that not only streamline production processes but also enhance food safety and sustainability. This blog will delve into the achievements of leading global manufacturers in the field, highlighting their commitment to exporting excellence in Industrial Food Processing Equipment. From advanced machinery designed for specific food products to cutting-edge automation systems, these companies are setting the benchmark for quality and efficiency. Join us as we explore the driving forces behind these industry leaders and how their innovations are shaping the future of food processing worldwide.

Key Players in the Global Industrial Food Processing Equipment Market

The global industrial food processing equipment market is witnessing significant growth, driven by rising consumer demand for processed foods and advanced processing technologies. In 2023, the global food processing equipment market was valued at approximately USD 45.01 billion, with projections to reach USD 79.70 billion by 2032, reflecting a robust compound annual growth rate (CAGR) in this sector. This upward trend highlights the integral role that innovative food processing solutions play in enhancing operational efficiency and product quality.

Moreover, the industrial refrigeration equipment market plays a pivotal role in the food processing industry, with a current market size estimated at USD 42.23 billion in 2023. This segment is expected to grow, reaching USD 70.05 billion by 2033 at a CAGR of 5.21%. As food safety standards intensify and the demand for clean-labeled products rises, manufacturers are increasingly investing in advanced refrigeration technologies to meet these challenges. The integration of sustainable practices within industrial refrigeration further emphasizes the industry's commitment to environmental responsibility while catering to evolving consumer preferences.

Innovative Technologies Revolutionizing Food Processing Equipment

In the rapidly evolving landscape of industrial food processing, innovative technologies are playing a pivotal role in revolutionizing how food is processed, packaged, and delivered. According to a recent report by Mordor Intelligence, the global food processing equipment market is projected to reach USD 80 billion by 2026, growing at a CAGR of 5% from 2021. This demand is primarily driven by the rising consumer preference for processed and convenience foods, leading manufacturers to adopt advanced technologies to improve efficiency and quality.

One of the key innovations shaping the industry is automation. The integration of robotics and AI in food processing not only enhances productivity but also improves precision in operations, reducing waste significantly. A study from the Food Processing Technology magazine highlights that automation can reduce labor costs by up to 30%, thereby enabling manufacturers to allocate resources more effectively while also ensuring consistent product quality. Moreover, advancements in machine learning algorithms are facilitating predictive maintenance, which minimizes downtime and prolongs equipment lifespan, further enhancing operational efficiency.

Furthermore, the utilization of smart technologies, such as IoT and data analytics, allows manufacturers to track and optimize their processes in real-time. This connectivity not only aids in quality control but also ensures compliance with stringent food safety regulations. The International Journal of Food Science & Technology reports that nearly 47% of food manufacturers are investing in IoT-enabled equipment, demonstrating a strong commitment to innovation and excellence in food processing. As these technologies continue to develop, they will undoubtedly shape the future of food manufacturing on a global scale.

Sustainability Trends Among Top Manufacturers in Food Processing

In the industrial food processing equipment sector, sustainability is becoming a cornerstone for top manufacturers aiming to enhance their global exporting capabilities. These companies are not only focused on improving efficiency but are also integrating eco-friendly practices into their production processes. By investing in energy-efficient machinery and reducing waste, they are paving the way for a more sustainable future within the food processing industry.

To align with these sustainability trends, manufacturers can adopt several key strategies. First, consider investing in renewable energy sources for your operations; solar panels and wind turbines can significantly reduce carbon footprints. Second, focus on optimizing production processes through lean manufacturing techniques that minimize waste. Lastly, explore partnerships with suppliers committed to sustainable practices, ensuring that every aspect of your supply chain meets environmental standards.

Moreover, educating employees about sustainability can foster a culture of innovation. Encourage teams to brainstorm new ideas for eco-friendly practices and product designs that not only enhance quality but also contribute positively to the environment. By taking these steps, leading manufacturers in food processing equipment can not only meet the demands of modern consumers but also establish themselves as industry leaders committed to sustainability.

The Role of Exporting Excellence in the Food Equipment Industry

In the competitive arena of industrial food processing equipment, exporting excellence is a crucial factor that can significantly define a manufacturer’s success. Companies that prioritize quality, innovation, and compliance with international standards can not only enhance their market presence but also build long-lasting relationships with global clients. An effective export strategy involves understanding diverse market needs and adapting products accordingly, ensuring that manufacturers can offer solutions that resonate with different cultural and operational practices.

Tip: Conduct thorough market research to identify trends and preferences in the target regions. This will allow manufacturers to tailor their offerings, thus improving their chances of successful exports.

Additionally, investing in robust supply chain management and quality assurance processes is vital. By optimizing logistics and maintaining stringent quality controls, manufacturers can ensure that their equipment meets the expectations of international clients. Timely deliveries and reliable after-sales support further bolster a company’s reputation, solidifying its position as a leader in the food equipment industry.

Tip: Develop strong partnerships with local distributors who understand the regional landscape and can provide valuable insights into customer preferences. This localized approach can significantly enhance market penetration and customer satisfaction.

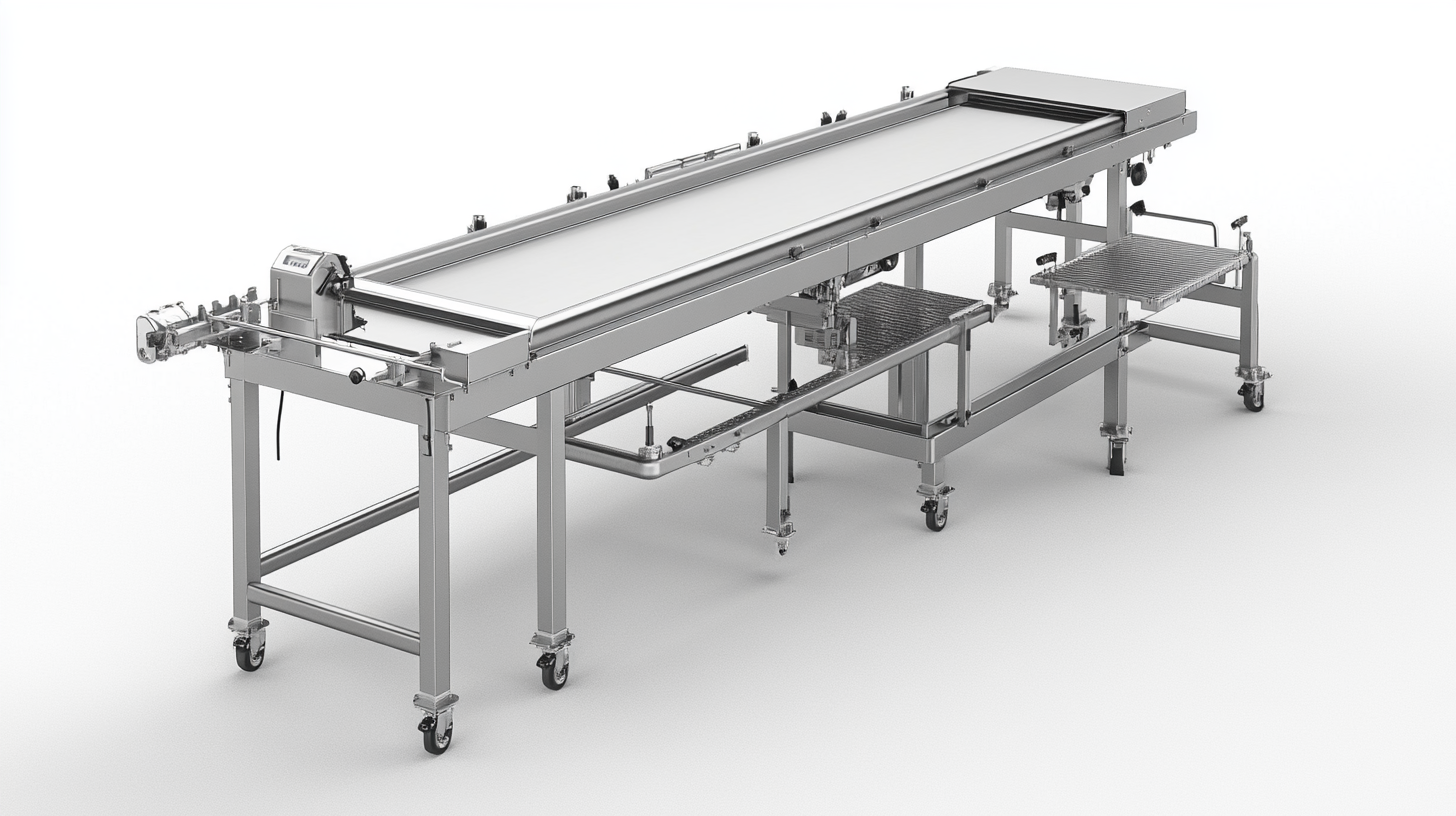

Leading Global Manufacturers in Industrial Food Processing Equipment

This chart illustrates the export performance of leading manufacturers in the industrial food processing equipment sector. The data highlights the export volumes of select companies over the past three years, demonstrating trends in exporting excellence.

Challenges and Opportunities for Global Food Processing Equipment Exporters

The global food processing equipment market is experiencing significant growth, with a projected rise from $130.6 billion in 2021 to $175.1 billion by 2025. This growth presents both challenges and opportunities for exporters in the sector. Manufacturers are consistently innovating their processes to enhance efficiency and reduce costs, which is crucial given the increasing demand for sustainable practices. However, the industry is also grappling with supply chain constraints that complicate the export landscape.

To effectively navigate these challenges, food manufacturers can implement several strategies. One crucial tip is to diversify supply sources to mitigate risks associated with over-reliance on a single supplier or region. Additionally, investing in technology and automation can streamline production processes and enhance flexibility in responding to market changes. By focusing on these areas, exporters can better position themselves to capitalize on the burgeoning opportunities within the global food processing equipment market. With a proactive approach to both challenges and innovations, the potential for growth remains robust.