What is Roll Lamination Machine and How Does It Work?

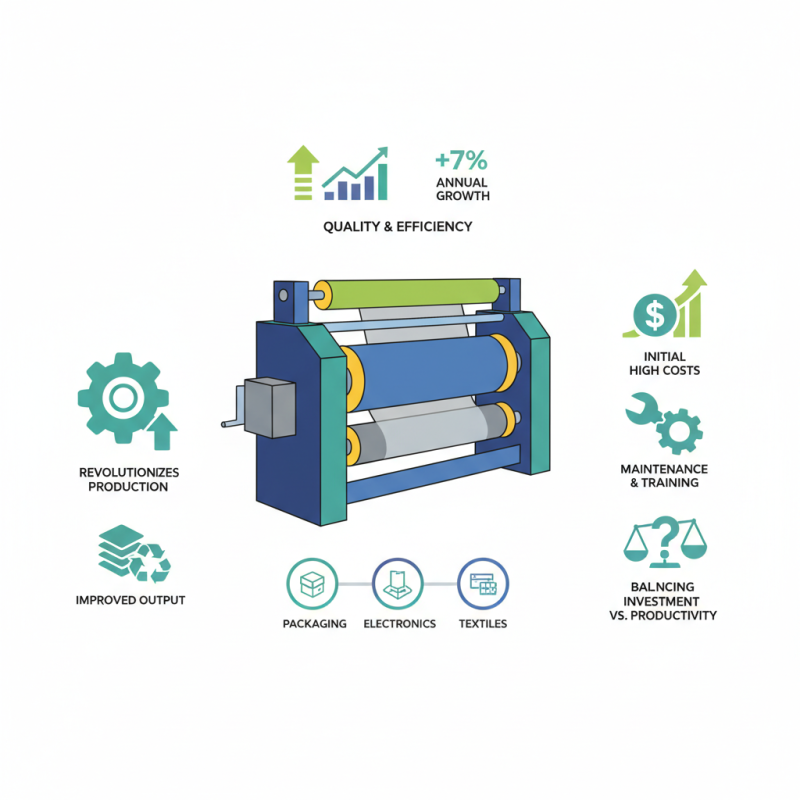

The Roll Lamination Machine is a pivotal technology in various manufacturing sectors. It enhances quality and efficiency in the lamination process. According to a report by market research firm Smith & Associates, the demand for roll lamination equipment is projected to grow by 7% annually. This indicates a broadening application in industries like packaging, electronics, and textiles.

Expert John Davis, a leading authority in lamination technology, stated, “The Roll Lamination Machine revolutionizes production lines, improving output and reducing material waste.” His insights highlight how essential this machinery has become. However, as industries adopt this technology, challenges arise. The initial costs can be high, and companies often struggle with maintenance and training.

Despite the clear advantages, some manufacturers still hesitate to invest in such machines, reflecting a disconnect in understanding their long-term benefits. Balancing the upfront investment with sustained productivity is not always straightforward. As the market evolves, a deeper reflection on these challenges can help industries fully embrace the capabilities of the Roll Lamination Machine.

Definition of Roll Lamination Machine and Its Purpose

A roll lamination machine is designed to apply a protective layer to various materials. This process enhances durability and strength. Typically used in packaging and product manufacturing, these machines offer efficiency and cost savings. The primary purpose is to seal items, ensuring they remain intact and presentable.

Data from industry reports indicate that roll lamination machines have become essential in sectors like food and electronics. In 2022, the global market for laminating machines reached approximately $1 billion. However, the effectiveness of these machines can depend on several factors. Material quality and temperature settings are crucial for optimal performance.

Users may face challenges, such as improper adhesive application or material misalignment. Such issues can lead to product waste or lower quality outputs. Continuous training and proper maintenance are necessary for the best results. Many companies still overlook this need, impacting their operational efficiency.

Roll Lamination Machine Efficiency by Application

This chart represents the efficiency of roll lamination machines across various applications. The efficiency percentage is an important metric that indicates how well the machines perform in packaging, printing, automotive, textiles, and electronics sectors.

Components of a Roll Lamination Machine and Their Functions

A roll lamination machine is essential for creating durable and high-quality laminated products. Understanding its components helps in grasping its functionality. The primary parts include rollers, a heating system, and a pressure mechanism. Each plays a vital role in the lamination process.

Rollers are where the lamination magic happens. They apply pressure and heat to the materials being processed. The heating system heats the laminating film, making it adhesive when pressed. It’s crucial that the temperature is accurately controlled. If it’s too low, adhesion fails; if too high, it can damage the materials. The pressure mechanism ensures that enveloping films bond properly, providing strength and longevity to the final product.

Quality control is essential. Operators must adjust settings correctly. An oversight can lead to bubbles or misalignment in the finished lamination. Regular maintenance of the machine is also vital but often overlooked. Slight wear on components can reduce efficiency and effectiveness. Understanding these elements helps users achieve better results. Proper training on each component is necessary for optimal performance.

What is Roll Lamination Machine and How Does It Work? - Components of a Roll Lamination Machine and Their Functions

| Component | Function |

|---|---|

| Feed System | Controls the input of the material into the machine for lamination. |

| Heater | Heats the adhesive used for lamination to ensure proper bonding. |

| Rolling Cylinders | Presses the layers together to achieve the desired laminate thickness. |

| Cooling System | Cools down the laminated product to solidify the adhesive. |

| Control Panel | Allows operators to set parameters and monitor the lamination process. |

| Cutting Mechanism | Cuts the laminated sheets to the desired size. |

The Process of Roll Lamination: Step-by-Step Guide

The roll lamination process involves several key steps. Initially, materials are prepared for lamination. This may include films, papers, or other substrates. Next, these materials are fed into the roll lamination machine. The machine uses heat and pressure to bond layers together.

During the lamination, rollers apply consistent pressure, ensuring adhesion. The process typically requires precise temperature control. Research indicates that improper temperature can reduce lamination quality by up to 25%. This emphasizes the need for accuracy in measurements and settings.

**Tips:**

Always monitor the temperature closely. Small discrepancies can lead to defects. Ensure even feeding of materials into the machine. Uneven feeding may snap or misalign layers, leading to waste. Frequent maintenance checks improve consistency and extend machine life.

Applications of Roll Lamination in Various Industries

Roll lamination is extensively used in several industries due to its versatility. This method enhances the durability of materials. In packaging, roll lamination protects products from moisture and abrasion. It ensures that items stay fresh and intact during storage and transportation.

In the automotive sector, roll lamination plays a crucial role. It is used in producing components like sound insulation materials. These laminated products provide better efficiency and comfort in vehicles. However, achieving the right balance of thickness and material type can be challenging.

In the construction industry, roll lamination aids in producing architectural elements. Laminated materials contribute to lightweight structures that require less energy. Yet, some companies struggle with ensuring consistent quality. It emphasizes that while roll lamination is beneficial, continuous improvement is necessary to maintain high standards.

Benefits of Using Roll Lamination Machine in Production

Roll lamination machines play a crucial role in modern manufacturing processes. These machines efficiently apply a protective film to various materials, enhancing durability and appearance. The benefits of using a roll lamination machine are substantial, especially for businesses aiming to improve product quality.

One significant advantage is the increased protection against wear and tear. Products that undergo lamination show improved resistance to moisture, dirt, and UV light. This feature extends the lifespan of items, reducing the need for replacements. However, not all laminations are perfect. Misalignment or air pockets can occur, creating imperfections in the finish.

Another key benefit is the enhanced aesthetic appeal. Lamination can add a glossy or matte finish, making products more attractive. This can positively impact consumer choice. Yet, the process can sometimes lead to color distortion or uneven surfaces. Manufacturers must pay attention to detail, ensuring every aspect aligns with quality standards. Regular maintenance of the machine prevents these issues and improves overall output.