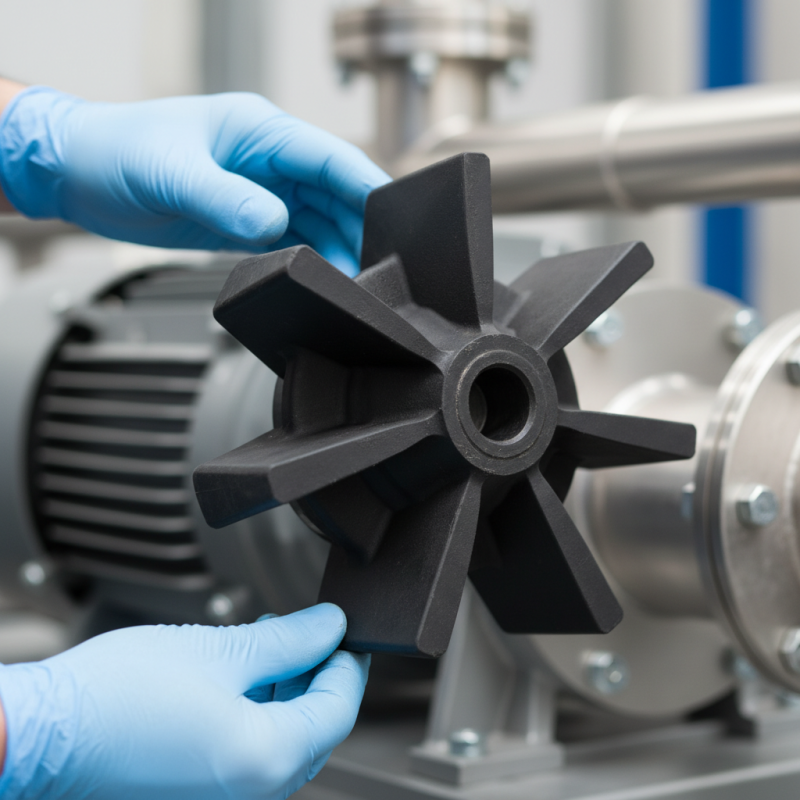

Rubber Pump Impeller Essential Tips for Optimal Performance?

In the world of fluid handling, the significance of the Rubber Pump Impeller cannot be overstated. Industry expert Dr. Sarah Johnson states, "The efficiency of a pump largely depends on the quality and design of its impeller." This highlights the critical role these components play in overall pump performance.

Rubber Pump Impellers are frequently used for their flexibility and resistance to wear. When properly maintained, they can enhance the lifespan of your pumping systems. Yet, many operators overlook crucial maintenance tips. This neglect can lead to inefficiencies and higher operational costs.

Common issues include misalignment and damage from abrasive fluids. Regular inspection can prevent these pitfalls. Proper installation is also vital but often disregarded. Minor adjustments could make a significant difference. Understanding the nuances of Rubber Pump Impellers is key to optimal performance. Investing time in these essential tips pays off in the long run.

Understanding the Role of Rubber Pump Impellers in Fluid Dynamics

Rubber pump impellers play a vital role in fluid dynamics. They are often the heart of the pumping system. The design and material selection can greatly influence efficiency. A well-designed impeller creates optimal flow patterns. However, improper installation or wear can lead to problems.

The fluid being pumped interacts with the impeller in unique ways. Changes in viscosity can affect performance. Sometimes, the impeller may not produce the expected results. This may require adjustments in speed or angle. Monitoring these factors is essential. Frequent inspections can reveal issues before they escalate.

Understanding the relationship between the impeller and the fluid is crucial. Operators should pay attention to the operating environment. Factors like temperature and pressure can change the dynamics. In some cases, using the wrong type of impeller can hinder overall performance. Reflecting on these elements will improve reliability and efficiency.

Key Factors Influencing Rubber Pump Impeller Performance

When considering rubber pump impellers, several key factors play a vital role in their performance. The materials used in the impeller significantly affect its durability and efficiency. Rubber compounds can vary widely, influencing both flexibility and resistance to wear. Selecting the right material can mean the difference between optimal and subpar operation.

Another critical factor is the design of the pump impeller. The shape and size directly affect hydraulic efficiency. An impeller that is too large may create excessive turbulence, while one that is too small may not generate enough flow. Additionally, wear over time can impact performance, creating potential inefficiencies. Regular assessment is necessary to identify these issues early on.

Operating conditions also greatly influence the impeller’s effectiveness. Factors like temperature and fluid characteristics can change the rubber’s behavior. For instance, extreme temperatures might cause the material to harden or degrade. Even minor changes in environmental conditions can lead to major performance shifts. It’s essential to monitor these variables to maintain peak efficiency.

Maintenance Practices for Enhancing Impeller Longevity

Rubber pump impellers are crucial for efficient fluid movement. Their performance directly impacts operational costs. Regular maintenance is essential to extend their lifespan. Reports suggest that well-maintained impellers can last up to 50% longer than those neglected. This statistics highlights the need for proper care.

Inspection is a key practice in maintenance. Check for wear and tear regularly. Replace impellers showing signs of damage. In addition, keep an eye on operating conditions. Abrasive materials can cause significant degradation. Adjusting the pump settings might be necessary. Remember, even small adjustments can prevent major issues.

Cleaning the impellers is equally important. Debris accumulation affects performance efficiency. A simple water rinse can help but often isn’t enough. Use mild cleaning agents when necessary. Caution is required here; harsh chemicals can degrade rubber quality. After cleaning, dry them completely before reassembling. These simple steps can enhance both performance and longevity.

Signs of Wear and Tear in Rubber Pump Impellers to Watch For

Rubber pump impellers play a crucial role in various applications. Over time, they can show signs of wear and tear. It's vital to monitor these indicators to maintain optimal performance. For instance, cracks or surface abrasions may appear. These can affect the efficiency of the pump. A simple visual inspection can reveal these issues.

Another common sign is reduced flow rate. If you notice a drop in performance, check the impeller. Deformations can hinder its function. Additionally, listen for unusual noises during operation. This could indicate further damage. Ignoring these signs can lead to bigger problems. Regular maintenance is essential.

It's easy to overlook minor signs at first. Often, users do not realize the importance of early detection. A worn impeller can cause costly downtime. Take time to examine the rubber components closely. By acknowledging these issues, you ensure the longevity of your pumping system. Don't wait for a complete failure to act. Being proactive can save time and money in the long run.

Rubber Pump Impeller Wear and Tear Analysis

Selecting the Right Rubber Material for Specific Pump Applications

Selecting the right rubber material for pump applications is crucial. Different applications require specific properties. For instance, fluid compatibility, temperature resistance, and wear endurance are important factors to consider.

Natural rubber is resilient and can handle moderate temperatures. However, it may not resist chemicals well. If your pump handles abrasives, consider Nitrile rubber. It offers good abrasion resistance, but its thermal stability is moderate. It can fail in extreme heat.

Sometimes, users overlook material selection. Testing the rubber in real-world conditions can reveal unexpected results. A seemingly suitable rubber might degrade quickly. Regular assessment is essential. Don't assume one type will work across all applications. Tailoring your choice to specific conditions promotes better performance.