What is a Steering Cylinder and How Does it Work?

A Steering Cylinder is a crucial component in many vehicles. It allows drivers to control the direction of their cars with precision. According to industry expert John Thompson, "The steering cylinder is the heart of steering systems." This simple yet powerful device facilitates the smooth navigation of vehicles.

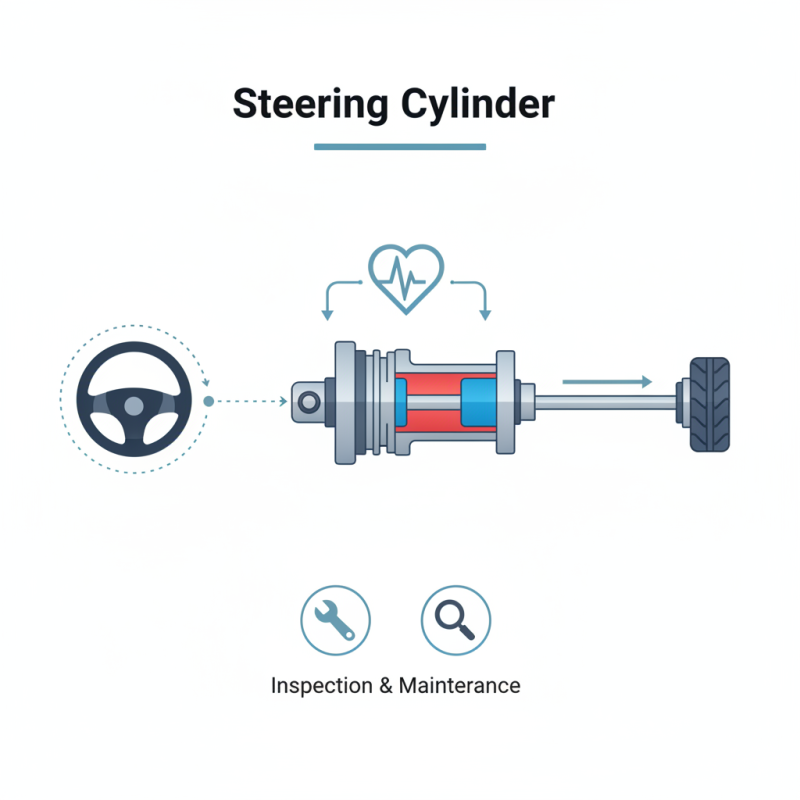

The steering cylinder operates by converting rotational input into linear motion. When the driver turns the steering wheel, the cylinder activates. This action provides the necessary force to steer the wheels. Understanding this mechanism is essential for any automotive engineer or enthusiast.

Despite its importance, many overlook the steering cylinder's role. Some may assume it's just another part. However, without it, precise steering would be impossible. Regular inspection and maintenance are vital for performance. Ensuring the steering cylinder functions properly can prevent accidents and enhance driving experiences. Reflection on its significance can lead to safer roadways for all.

What is a Steering Cylinder? An Overview of Its Definition and Function

A steering cylinder is a crucial component in hydraulic steering systems. It plays a significant role in helping vehicles maneuver effectively. The steering cylinder converts hydraulic pressure into mechanical force, allowing the wheels to turn. This process enhances a driver's control over the vehicle, especially in challenging conditions. According to a report by Markets and Markets, the global hydraulic steering market is expected to reach USD 12.1 billion by 2027, highlighting the growing importance of these systems.

The core function of a steering cylinder lies in its design. It consists of a piston inside a cylindrical chamber. When hydraulic fluid is pumped into the chamber, the pressure pushes the piston. This action results in the turning motion of the steering wheel. However, the system can face challenges, such as leaks or pressure losses. An observed issue is that even a minor leak can cause significant steering difficulties. Industry reports indicate that up to 20% of hydraulic failures stem from these issues, underlining the need for regular maintenance.

The Mechanism Behind Steering Cylinders: How Do They Operate?

Steering cylinders play a crucial role in the steering system of vehicles. They help to convert the rotational motion of the steering wheel into the linear motion needed to turn the wheels. This involves complex hydraulic or mechanical principles that ensure smooth and precise steering.

Typically, hydraulic steering cylinders operate through pressurized fluid. As the driver turns the steering wheel, hydraulic pressure is generated. This pressure pushes the cylinder's piston, moving the connected steering linkage. Reports indicate that modern hydraulic systems can improve steering responsiveness by up to 30%. This makes small adjustments easier, enhancing overall vehicle control.

However, while steering cylinders are essential, they are not without flaws. The effectiveness can decrease as seals wear out. Additionally, hydraulic leaks can lead to a loss of steering power, creating safety risks. Regular maintenance checks are necessary to ensure optimal performance. Industry statistics show that neglected steering systems contribute to 15% of vehicle accidents. Such data emphasizes the importance of understanding the steering mechanism fully, ensuring safe driving.

Key Components of Steering Cylinders: Analyzing Their Roles and Design

Steering cylinders play a crucial role in hydraulic steering systems. They convert hydraulic pressure into linear motion, allowing for precise vehicle steering. The key components of these cylinders include the cylinder barrel, piston, and seals. Each part is necessary for the system's overall functionality.

The cylinder barrel houses the piston. It is designed to withstand high pressures. For example, hydraulic steering systems operate at pressures around 1,500 to 2,500 psi. The piston moves within the barrel, altering the fluid dynamics. Seals are essential too. They prevent leaks, ensuring system efficiency.

Design flaws can lead to performance issues. Poor seal quality might cause fluid leaks, reducing steering effectiveness. Engineers focus greatly on material selection. Steel and aluminum are common, but their durability can vary. Sometimes, tests show that high-stress areas wear out faster than expected. Continuous improvement in manufacturing processes is vital. This can enhance the longevity of steering cylinders significantly.

What is a Steering Cylinder and How Does it Work?

| Component | Function | Material Used | Common Applications |

|---|---|---|---|

| Steering Cylinder | Converts hydraulic pressure into linear motion | Aluminum, Steel | Heavy-duty vehicles, Agricultural machinery |

| Piston | Moves within the cylinder to create force | Forged Steel | Automobiles, Construction equipment |

| Seals | Prevents fluid leakage and contamination | Nitrile Rubber | Hydraulic systems, Marine equipment |

| Rod | Transmits motion from the piston to the steering mechanism | Carbon Steel | Forklifts, Trucks |

| Body | Houses all components of the steering cylinder | Cast Iron | Buses, Tractors |

Applications of Steering Cylinders in Various Industries and Machinery

Steering cylinders are critical in various industries, enabling precise control and maneuverability. In agriculture, for instance, steering cylinders facilitate the operation of tractors and harvesters, enhancing efficiency. According to industry reports, nearly 65% of modern tractors rely on hydraulic steering systems for optimal performance.

In construction machinery, steering cylinders are essential for excavators and bulldozers. They provide the necessary force to turn heavy machinery effectively. Research indicates that the use of hydraulic steering can improve response times by 30% compared to traditional systems. This reduction in response time can significantly affect productivity on job sites.

Additionally, steering cylinders are used in marine applications. Boats and ships utilize these components for steering and stabilization. The marine industry has seen a shift toward more advanced hydraulic systems, improving safety and navigation. However, not all manufacturers adopt the latest technologies, leading to inefficiencies and safety risks. The evolution of steering systems demonstrates both progress and areas needing further reflection in engineering design.

Applications of Steering Cylinders in Various Industries

Maintenance Tips for Steering Cylinders: Ensuring Optimal Performance

Steering cylinders play a crucial role in various machinery, ensuring smooth navigation and control. Regular maintenance is essential for these components to function optimally. One effective tip is to regularly inspect for leaks. A small leak can lead to significant problems. Look for any signs of oil around the cylinder. It often indicates a worn seal that needs replacing.

Another key practice is to check the fluid levels frequently. Low levels can cause the cylinder to operate less efficiently. Using the correct hydraulic fluid is also important. Not all oils are created equal. Contaminated or incorrect fluid can damage the system over time.

Cleaning the cylinder and its components is often overlooked. Dirt and debris can hinder performance. Simple cleaning can extend the life of the cylinder. Additionally, consider the operating environment. If you work in harsh conditions, schedules should be more frequent. Ignoring these factors might lead to costly repairs later on. Addressing minor issues promptly will prevent larger, more intricate failures in the future.