Top Tips for Choosing the Right Damper Actuator?

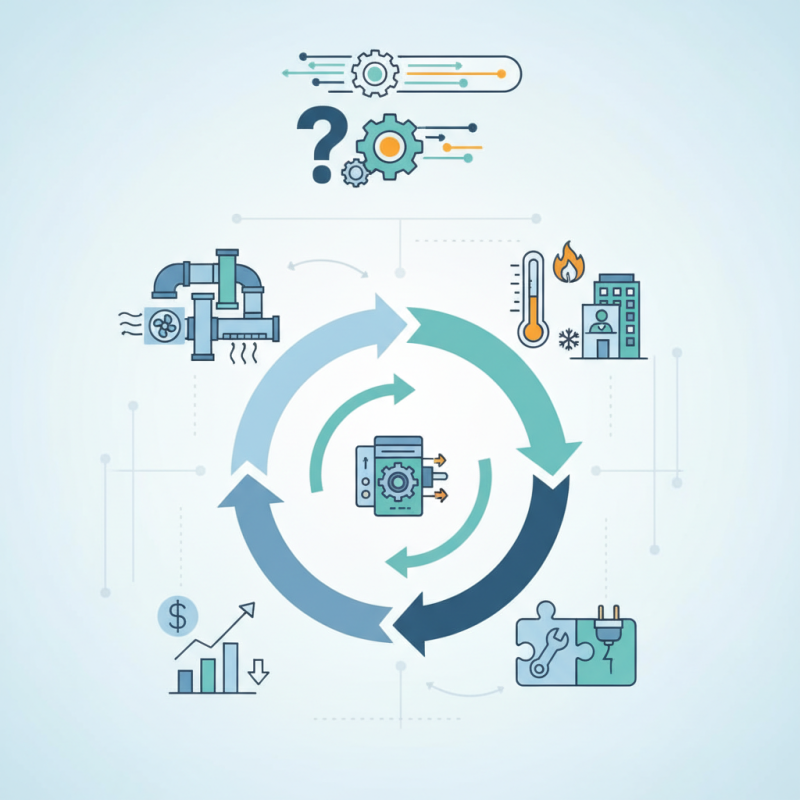

Choosing the right Damper Actuator is vital for effective HVAC systems. The actuator plays a key role in how air flows through ducts. An improper selection may lead to inefficient operation, increasing energy costs.

Understanding your specific needs is crucial. Consider the type of system you have. Different systems require different actuators. The environment also matters. For instance, extreme temperatures can impact actuator performance.

Many users overlook compatibility. An actuator must fit your existing setup. Recognizing this need can prevent costly mistakes. Reflecting on your choices helps to identify the best option. In the end, a well-chosen Damper Actuator can optimize airflow and enhance comfort.

Understanding Damper Actuators: Types and Functions

Damper actuators play a crucial role in HVAC systems. They control airflow and maintain indoor air quality. Understanding their types helps in making informed decisions.

There are two main types of damper actuators: electric and pneumatic. Electric actuators provide precise control. They are often easier to install and adjust. Pneumatic actuators, however, rely on compressed air. They can be less flexible but sturdy in certain applications. Each type has its advantages. It’s essential to consider the specific needs of your system.

When choosing an actuator, think about the environment. Temperature fluctuations affect performance. Also, review design constraints like space and mounting options. Poor selection may lead to inefficiencies. Reflecting on your requirements will guide better choices. Take time to compare options and visualize their integration. Every detail matters in achieving optimal airflow management.

Key Factors to Consider for Selecting a Damper Actuator

When selecting a damper actuator, several key factors come into play. The actuator type must match the system's requirements. Electric, pneumatic, and hydraulic options exist. Each has unique strengths and weaknesses. Electric actuators are precise but might lack the power for large dampers. Conversely, pneumatic actuators excel in speed but can be less accurate. Data suggests that 45% of HVAC failures stem from mismatched actuators.

Another vital factor is torque rating. This rating determines how much force the actuator can apply. If an actuator is undersized, it can lead to improper operation. In some cases, this can result in increased energy consumption—up to 20% higher than expected. It’s crucial to assess the damper size and system pressure to avoid this issue. A torque rating that is too low can cause wear and tear, leading to premature failure.

Installation complexity should also be considered. Some actuators require intricate setups. It's wise to review installation guides thoroughly. User reviews often highlight the challenges faced during installation, providing valuable insights. 68% of installers report frustration due to unclear instructions. Choosing the right damper actuator requires careful consideration of these factors. Balancing performance, efficiency, and ease can be difficult but essential for optimal results.

Evaluating Performance Metrics of Damper Actuators

When evaluating the performance metrics of damper actuators, several key factors are essential. The actuator's response time is crucial, particularly in HVAC systems. According to industry research, optimal response times can range from 0.1 seconds to 2 seconds. Delays beyond this may lead to inefficient air distribution and increased energy costs.

Another important metric is the torque output. Actuators need adequate torque to handle various damper sizes and resistances. Reports suggest that a torque range of 5 to 15 Nm is common for most applications. Choosing an actuator with insufficient torque may result in failure to operate under load, which can lead to system downtime.

Moreover, the duty cycle of the actuator must not be overlooked. Continuous operation can lead to overheating issues. A typical duty cycle recommendation is 50% for best performance, meaning the actuator should rest as much as it operates. Many overlook this detail, impacting actuator longevity. Balancing these metrics can significantly enhance system efficacy, yet many are left guessing about optimal choices.

Performance Metrics of Damper Actuators

Compatibility and Integration with Existing Systems

When selecting a damper actuator, compatibility and integration should be your main focus. Ensuring that the actuator fits seamlessly into your existing systems is crucial. Check the specifications of your current setup. Measure the overall dimensions and connections. Small discrepancies can lead to major failures.

Consider the communication protocols used by your existing devices. Actuators must be able to communicate effectively with sensors and controllers. Look for compatibility with MODBUS, BACnet, or other relevant protocols. It's not just about fitting physically; it’s about functioning well together.

Energy efficiency is another factor to ponder. An actuator that works well with your current system can save costs long-term. An error in this area can lead to wasted energy and increased bills. Assess the power ratings carefully. Sometimes, an actuator might look great on paper but struggle in real applications. Don’t ignore field tests. Practical evaluations often reveal weaknesses that specs don’t capture.

Maintenance and Longevity Considerations in Damper Actuator Selection

When selecting damper actuators, maintenance and longevity are critical factors. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) shows that proper maintenance can increase actuator lifespan by 30%. Regular checks can prevent unexpected failures and costly replacements.

Choosing the right materials is crucial. Corrosion-resistant components extend actuator life, especially in harsh environments. Data indicates that stainless steel models resist wear better than standard materials. Users should also consider the actuator's load and control frequency. High demands lead to fatigue, and neglected maintenance can reflect poor selection.

Installation plays a significant role too. Improperly aligned actuators can lead to premature wear. Reports highlight that over 40% of actuator failures stem from installation errors. Frequent inspection and balancing are often overlooked. These details can significantly impact performance and durability. Long-term success requires attention to these finer aspects.

Top Tips for Choosing the Right Damper Actuator - Maintenance and Longevity Considerations in Damper Actuator Selection

| Criteria | Considerations | Maintenance Tips | Expected Longevity |

|---|---|---|---|

| Type of Actuator | Choose between electric, pneumatic, or hydraulic based on application needs. | Regularly inspect and clean the actuator to prevent buildup. | 5-10 years depending on usage and maintenance. |

| Control Signal | Match the actuator control signal type (0-10V, Modbus) to system requirements. | Test control signal integrity regularly. | 7-12 years with proper signal monitoring. |

| Environment | Consider temperature, humidity, and exposure to chemicals. | Use environmental enclosures if needed. | 3-8 years depending on environmental conditions. |

| Mounting Position | Select appropriate mounting position for optimal performance. | Check mounting screws and fittings regularly. | 4-9 years with correct installation. |

| Size and Torque | Ensure actuator size and torque ratings match application requirements. | Monitor torque output for signs of wear. | 5-15 years with load management. |