5 Essential Trends in Commercial Meat Processing Equipment for Global Buyers

In the ever-evolving landscape of the meat processing industry, the demand for innovative Commercial Meat Processing Equipment is at an all-time high. As global buyers seek to enhance efficiency, safety, and sustainability within their operations, understanding the latest trends becomes paramount. This blog aims to shed light on five essential trends transforming the commercial meat processing sector, providing valuable insights for stakeholders looking to stay ahead in this competitive market.

As we delve into these trends, we will explore advancements in technology, shifts towards automation, and the increasing emphasis on sustainability. Each of these factors plays a crucial role in shaping the future of Commercial Meat Processing Equipment, ensuring that businesses not only meet consumer expectations but also comply with stricter regulations. Join us as we uncover these key trends, equipping global buyers with the knowledge needed to make informed decisions in their procurement strategies.

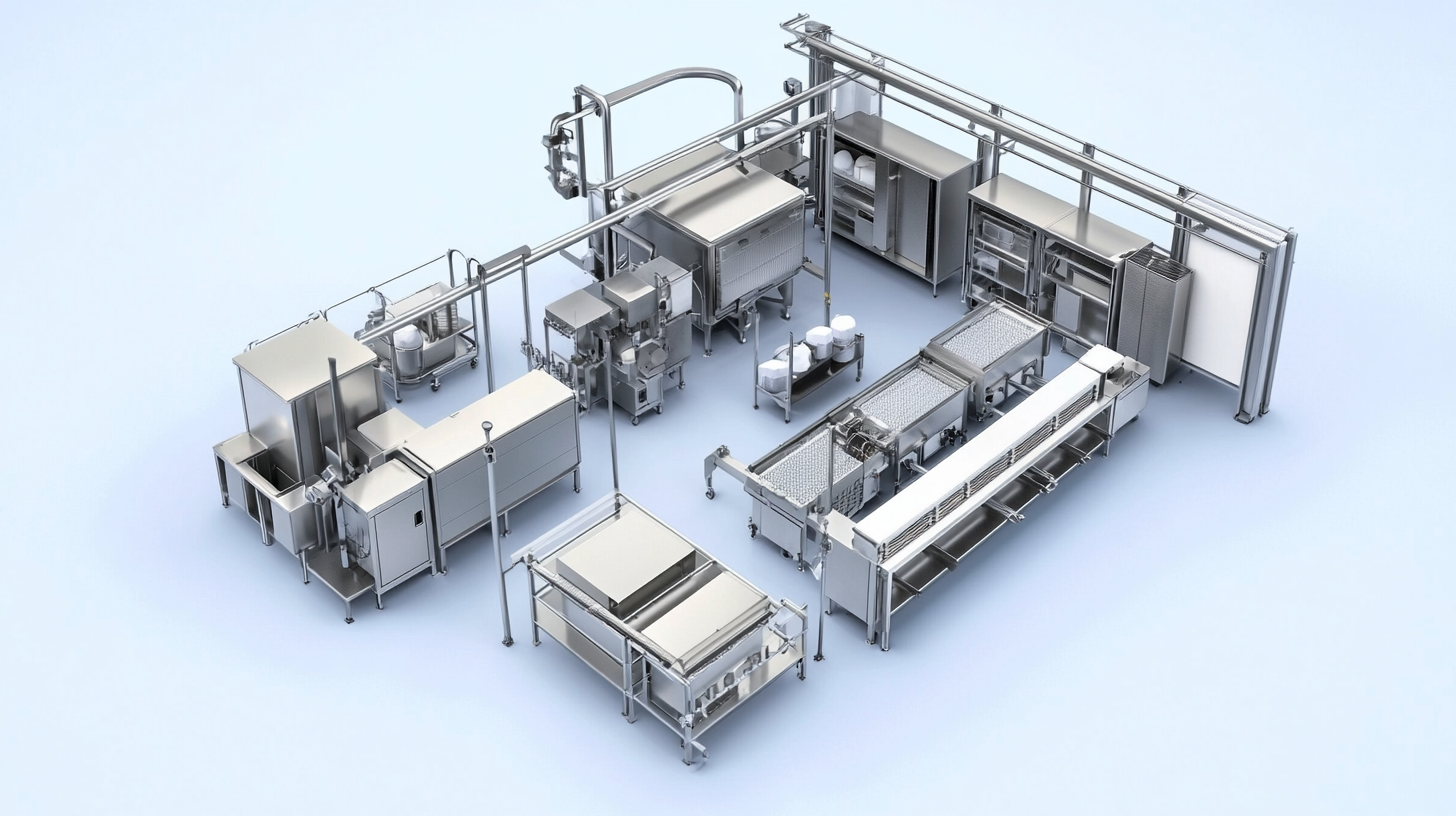

Emerging Automation Technologies in Meat Processing Equipment

Emerging automation technologies are redefining the landscape of meat processing equipment, offering unprecedented efficiency and precision for global buyers. As the demand for higher productivity increases, the integration of advanced robotics and artificial intelligence into processing lines helps businesses streamline operations and reduce labor costs. Automation systems can now seamlessly handle repetitive tasks such as cutting, grinding, and packaging, allowing human workers to focus on more complex activities that require critical thinking and finesse. Moreover, smart technologies are enhancing product traceability throughout the meat processing chain. IoT-enabled devices facilitate real-time monitoring of equipment performance and product quality, ensuring compliance with safety standards and reducing waste. This level of connectivity not only improves operational efficiency but also fosters transparency with consumers who demand higher accountability regarding food safety and quality. Furthermore, the rise of data analytics in meat processing equips manufacturers with the ability to make informed decisions based on insightful patterns. By analyzing production data, businesses can identify bottlenecks, optimize workflows, and predict maintenance needs, thus minimizing downtime. As global buyers navigate the evolving landscape of meat processing equipment, embracing these automation technologies will be key to staying competitive in an increasingly automated industry.

Sustainability Practices Shaping the Future of Meat Production

The future of meat production is increasingly influenced by sustainable practices, driven by both consumer demand and regulatory changes. As awareness of climate change grows, the meat processing industry is facing pressure to reduce its environmental impact. This has led to innovative solutions, such as the application of single-use bioreactors for cultured meat production. These bioreactors not only streamline the production process but also minimize waste, signalling a significant shift towards more sustainable methods.

In addition to technological advancements, there is a growing recognition within the farming community in Europe of the need for dietary shifts. Reports published by farming lobbies advocate for a shared vision of reducing meat consumption, highlighting a collective commitment to feasible reforms in agriculture. This dialogue between agricultural stakeholders and environmental groups underlines the urgency to implement sustainable practices that align with the aim of reducing greenhouse gas emissions.

Furthermore, investments in alternative proteins, such as lab-grown meat, are gaining traction among major influencers. High-profile funding initiatives are supporting research and development efforts to create sustainable food sources that could lessen reliance on traditional meat production. This shift not only addresses the growing global food demand but also aligns with the pressing need to rethink our consumption patterns to achieve a climate-friendly future.

Innovative Food Safety Measures in Commercial Meat Processing

In the ever-evolving landscape of commercial meat processing, innovative food safety measures are at the forefront of industry advancements. As global buyers seek reliable and safe meat products, the integration of cutting-edge technology and adherence to stringent safety protocols has become paramount. Recent literature highlights the concern of foodborne pathogens, underlining the importance of comprehensive food safety strategies that address potential risks at every stage of the meat production process. Advanced tracking systems and microbial testing technologies are now essential components in ensuring that products meet safety standards and maintain consumer trust.

Moreover, with initiatives like those in Hawaii to encourage home cooks to engage in food production, the conversation around meat safety and regulation gains even more significance. This push for greater participation in the food system necessitates clear guidelines and safety measures to protect consumers from risks associated with homemade meat products. This is where the response of the meat processing industry becomes crucial. Embracing modern practices, such as Hazard Analysis Critical Control Point (HACCP) systems and automation, companies like Litera Meat are setting new benchmarks for quality and safety, establishing a framework for both traditional and innovative food producers to follow.

As the meat industry adapts to these emerging trends, the emphasis on consumer acceptance cannot be overlooked. Understanding and addressing the concerns around food safety through transparent practices help align consumer preferences with production methods. The focus on food safety is not merely a regulatory obligation but also a vital aspect of maintaining market viability, especially as alternative proteins and plant-based trends continue to shape consumer behavior. By prioritizing food safety measures, the commercial meat processing sector can foster confidence and uphold the integrity of its products in a competitive global marketplace.

The Role of IoT in Enhancing Meat Processing Efficiency

The integration of the Internet of Things (IoT) in the meat processing industry is revolutionizing operational efficiency and product quality. According to a report by MarketsandMarkets, the global IoT in the food and beverage market is projected to grow from $5.8 billion in 2023 to $16.0 billion by 2028, highlighting the increasing importance of connected devices in enhancing productivity. In meat processing, IoT applications enable real-time monitoring and data analytics, allowing producers to optimize their processes and reduce waste.

By employing IoT technology, meat processors can track environmental conditions such as temperature and humidity, which are critical for food safety. A recent survey from Rabobank indicated that processors utilizing IoT solutions reported up to a 20% reduction in spoilage rates. This is particularly significant in an industry where maintaining product integrity is paramount. Furthermore, predictive maintenance powered by IoT sensors can alert operators to equipment malfunctions before they escalate, reducing downtime and saving on repair costs.

The advent of smart processing equipment equipped with IoT capabilities is also enhancing traceability throughout the meat supply chain. As confirmed by a study from the Food Processing Suppliers Association, 65% of consumers express a desire for better transparency regarding the origins of their food. IoT solutions facilitate this by capturing data at every step of production, leading to improved compliance with regulations and heightened consumer trust. Overall, the synergistic relationship between IoT and meat processing underscores a future where efficiency and safety are paramount.

Trends in Customized Equipment to Meet Diverse Market Needs

The commercial meat processing equipment industry is increasingly embracing trends in customization to cater to diverse market needs. As global buyers seek more tailored solutions, manufacturers are responding by developing equipment that can be easily adapted to specific operational requirements. This trend reflects a broader shift across various industries, where personalization is becoming a key differentiator in product offerings. Customized equipment not only enhances efficiency and production capabilities but also aligns with the unique preferences of different markets, ensuring that companies remain competitive.

In tandem with the rise of customization, the demand for advanced technology integration in meat processing equipment is also on the rise. Companies are now looking for solutions that incorporate the latest advancements in automation, data analytics, and ergonomics, allowing for improved operational workflows and worker safety. This is particularly relevant as businesses strive to enhance productivity while maintaining strict quality and safety standards.

Moreover, the focus on sustainable practices is transforming how meat processing equipment is designed and manufactured. Buyers are increasingly drawn to equipment that minimizes waste, enhances energy efficiency, and uses eco-friendly materials. This alignment with sustainability trends not only meets regulatory requirements but also resonates with a growing base of environmentally conscious consumers. As these trends evolve, it’s clear that adaptability and a focus on customer-centric innovations will be crucial for success in the commercial meat processing sector.