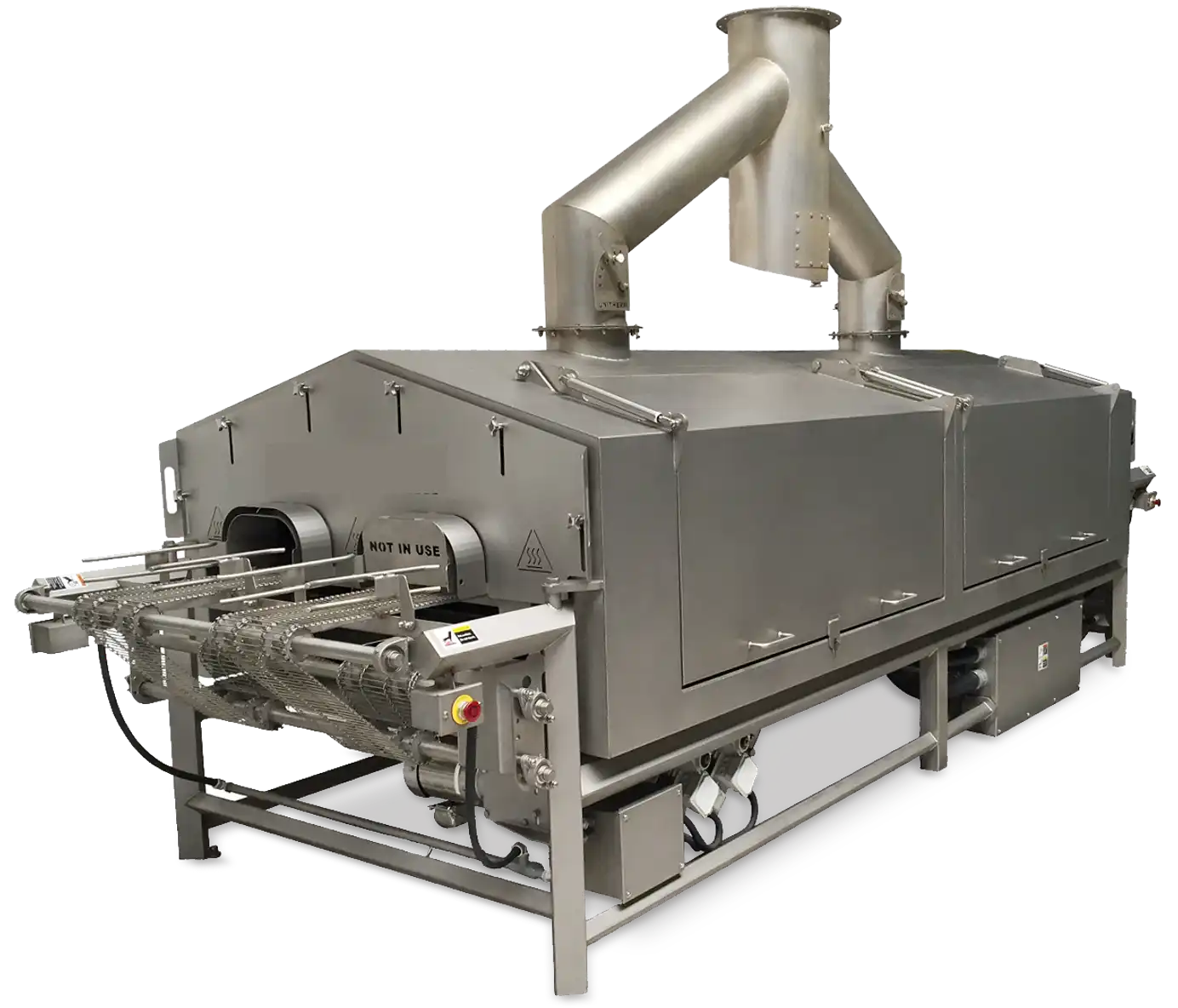

Afoheat™ Infrared Pasteurizer

Our Afoheat™ Infrared Pasteurizer is a continuous grill equipped with patented electric infrared technology.

TheMini Infrared Pasteurizerincludes machine-mounted prewired controls and independent bottom infrared controls.

TheDual-Lane Infrared Pasteurizerhas independent bottom infrared control and heats product on top, sides and bottom. It includes removable heat shields, removable drop trays for easy sanitation and an inline belt wash.

The flexibility of the design has led to installations for a variety of applications including pre-package pasteurization and surface treatment of both bulk and convenience foods. At the core of the design concept are standardized models with a compact footprint. The Infrared Pasteurizers offer processors lots of flexibility and can be used as a standalone solution or integrated into any continuous thermal processing line. The control system adjusts the electric power to top and bottom independently for precision results in terms of product color and enhanced flavor profile.

- Product Family: Pre-package Pasteurization

Features

- Pasteurize, sear, roast, brown, or grill

- Infrared heats product on top, sides, and bottom

- Independent bottom infrared control

- Machine-mounted prewired controls

- Create, edit, and store recipes

- Preassembled and tested, installation ready

- Removable drip trays

- Inline belt wash

- Exhaust fan

- EWON for remote data logging

- US Patent 6,867,392 B1

Specs

Mini Infrared Pasteurizer Specs:

- Footprint: 6′ (1.83 m) L x 3.16′ (.96 m) W x 6.25′ (1.91 m) H

- Conveyor: 11″ (280 mm) W

- Conveyor Speed: 15-120 seconds average. Up to 65′ (20 m) per minute

- Product Clearance: 8″ (200 mm)

- Electrical Supply: USA: 480V AC, 3 Ph, 50 Amp, 60 Hz / EUR: 380V AC, 3 Ph, 60 Amp, 50 Hz

- Water Supply: 1/2″ (12 mm) NPT main supply

- Drain: 2-1/2″ (75 mm) sanitary clamp

- Exhaust: Up to 900 CFM at ½” (12 mm) WC or 25 m³/min at 1.25 millibar 8″ (200 mm) flange

Dual-Lane Infrared Pasteurizer Specs:

- Footprint: 16.3′ (4.98 m) L x 8.75′ (2.66 m) W x 11.41′ (3.47 m) H

- Conveyor: Two lanes; each 11″ (280 mm ) W

- Conveyor Speed: 15-120 seconds average. Up to 65′ (20 m) per minute

- Product Clearance: Up to 8″ (200 mm)

- Electrical Supply: USA: 480V AC, 200 AMP, 3PH, 60 Hz / AUS: 415V AC, 230 AMP, 3PH, 50Hz / EUR: 380V AC, 250 AMP, 3PH, 50 Hz

- Water Supply: 1/2″ (12 mm) NPT main supply, 60 GPH

- Drain: 3″ (75 mm) sanitary clamp

- Exhaust: Up to 900 CFM at ½” (12 mm) WC or 25 m³/min at 1.25 millibar. 8″ (200 mm) flange

- Extraction Utility: 2 x 10.625″ (270 mm) Outlet; Y Duct w/15″ (381 mm) Fan; Up to 3,500 CFM (99 m3/min.) Total